Content

- 1 Structural Role of an Extruded Aluminum Sill in Door and Window Systems

- 2 Extrusion Profile Design and Functional Geometry

- 3 Drainage Performance and Water Management Logic

- 4 Aluminum Alloy Selection and Mechanical Properties

- 5 Surface Finishing and Environmental Durability

- 6 Installation Interfaces and Subfloor Compatibility

- 7 Thermal Considerations and System Integration

Structural Role of an Extruded Aluminum Sill in Door and Window Systems

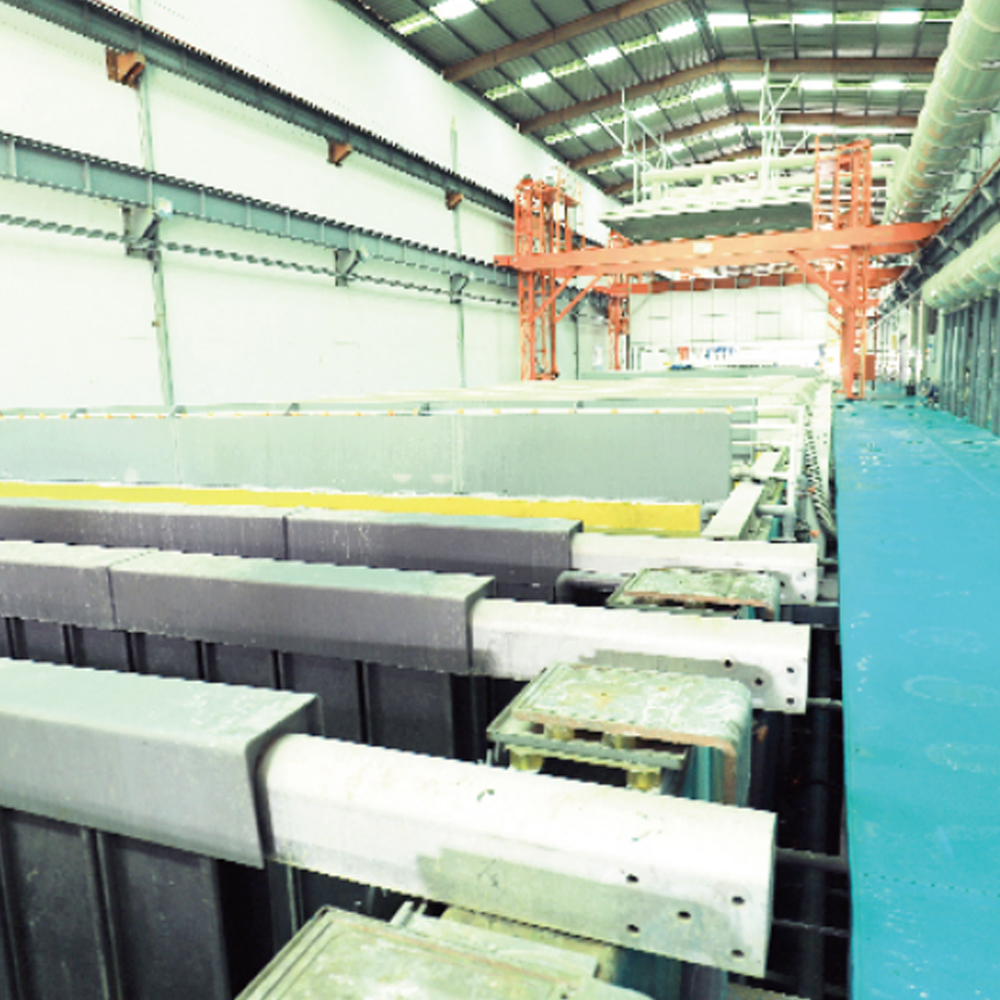

An extruded aluminum sill is not a decorative accessory. It functions as a structural interface between the frame system and the building substrate, carrying localized loads from foot traffic, door operation, and frame weight. The extrusion profile determines how loads are transferred to the subfloor or threshold support, reducing point stress that could otherwise lead to deformation or seal failure. Well-designed sill profiles include reinforced webs or ribs to maintain stiffness while keeping overall weight manageable.

From a system perspective, the sill also acts as a reference plane for frame alignment. Variations in sill flatness directly affect sash operation, gasket compression, and long-term performance of sliding or hinged doors. This makes extrusion accuracy and dimensional tolerance control critical during manufacturing.

Extrusion Profile Design and Functional Geometry

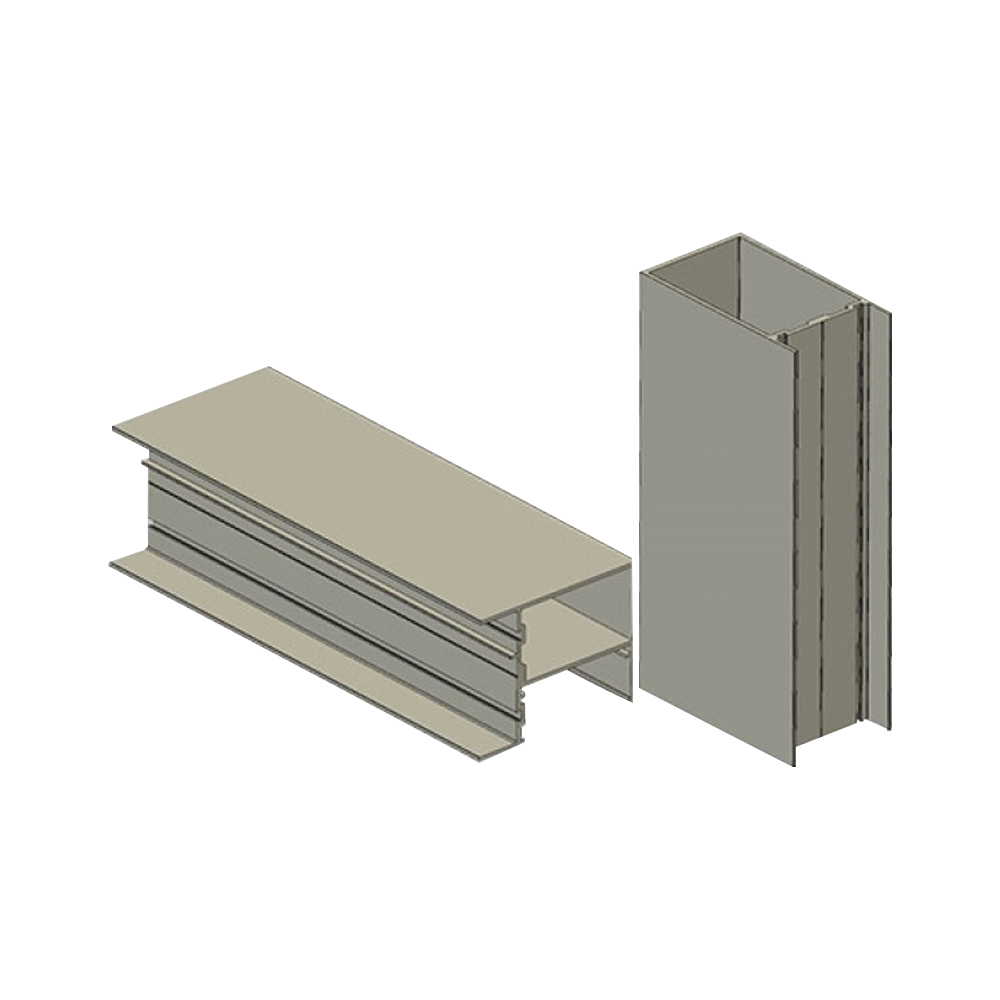

The geometry of an extruded aluminum sill defines how it manages water, air, and mechanical interaction with the door or window frame. Common profiles integrate multiple functional zones rather than a single flat surface. These zones are engineered into the extrusion itself rather than added later, improving consistency and durability.

- Load-bearing platforms designed to support rolling door panels or concentrated foot traffic

- Drainage channels that direct water away from the interior edge

- Raised or sloped surfaces that limit standing water accumulation

- Interlocking grooves for frame attachment, gaskets, or thermal break inserts

Because extrusion allows complex cross-sections without secondary machining, these features can be integrated with tight repeatability, which is difficult to achieve with fabricated or cast sill alternatives.

Drainage Performance and Water Management Logic

Water management is one of the most critical performance aspects of an extruded aluminum sill. Unlike surface-mounted thresholds, extruded sills often incorporate internal drainage paths that work together with the frame system. These channels collect water that passes the exterior gasket and redirect it toward designated weep outlets.

The slope angle of the sill surface, the depth of drainage channels, and the position of weep exits are all defined at the extrusion stage. This ensures consistent drainage behavior across multiple units. Inadequate channel depth or poorly positioned outlets can lead to water retention, increasing the risk of corrosion at fastener points and seal degradation over time.

Aluminum Alloy Selection and Mechanical Properties

Extruded aluminum sills are typically produced from architectural-grade aluminum alloys selected for a balance of strength, corrosion resistance, and extrudability. Alloy choice affects not only mechanical performance but also surface finish quality and long-term stability in different environments.

| Alloy Type | Key Characteristics | Typical Application Focus |

| 6000 Series | Good strength, stable extrusion, suitable for anodizing | Residential and commercial door sills |

| 5000 Series | Higher corrosion resistance, moderate strength | Coastal or high-humidity environments |

Surface Finishing and Environmental Durability

Surface treatment extends the service life of an extruded aluminum sill and affects how it interacts with adjacent materials. Anodizing creates a controlled oxide layer that improves corrosion resistance while maintaining dimensional accuracy. Powder coating adds color flexibility and enhanced surface protection, but requires careful control of coating thickness to avoid interference with frame fit.

Finish selection should consider exposure conditions, foot traffic frequency, and cleaning methods. Abrasive cleaning practices can damage certain finishes, reducing both appearance and protective performance.

Installation Interfaces and Subfloor Compatibility

The effectiveness of an extruded aluminum sill depends heavily on how it interfaces with the subfloor and surrounding construction layers. Proper installation requires attention to flatness, sealing continuity, and fastener placement. Uneven substrates can introduce twist into the sill, compromising drainage and frame alignment.

Compatibility with different subfloor materials, such as concrete, wood, or steel framing, should be evaluated during system design. Each substrate type may require specific anchoring methods and sealant strategies to maintain long-term stability.

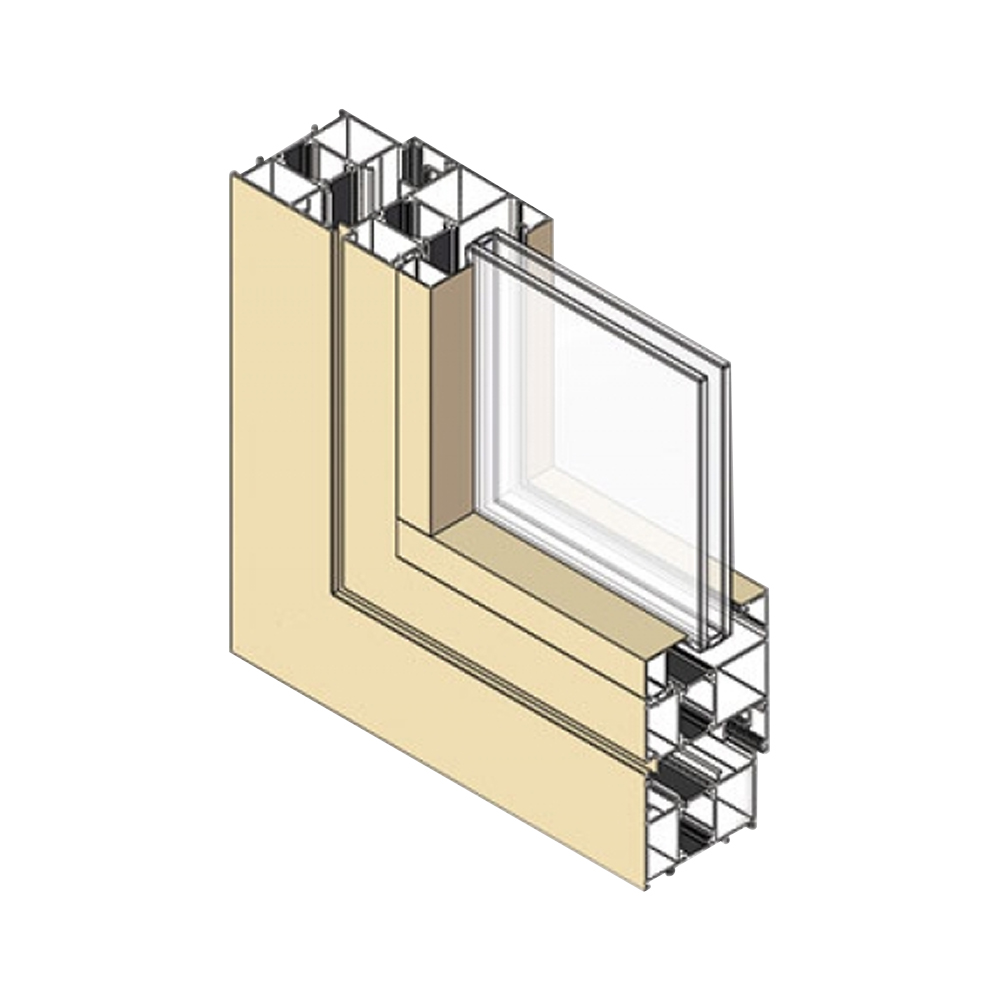

Thermal Considerations and System Integration

Although aluminum offers structural advantages, it is also a conductive material. Modern extruded aluminum sills often integrate thermal break zones or are designed to work in conjunction with insulated frame systems. These measures help reduce thermal bridging at the threshold, improving overall building envelope performance.

Proper coordination between sill design, frame insulation, and floor insulation layers ensures that thermal performance targets are met without compromising structural integrity or water management.

English

English 日本語

日本語 한국어

한국어