-

Aluminum Profiles Surface Treatment Aluminum Profiles Surface Treatment

Aluminum Profiles Surface Treatment Aluminum Profiles Surface Treatment -

Automotive Parts CNC Machining Industrial Automotive Parts Precision Machining

Automotive Parts CNC Machining Industrial Automotive Parts Precision Machining -

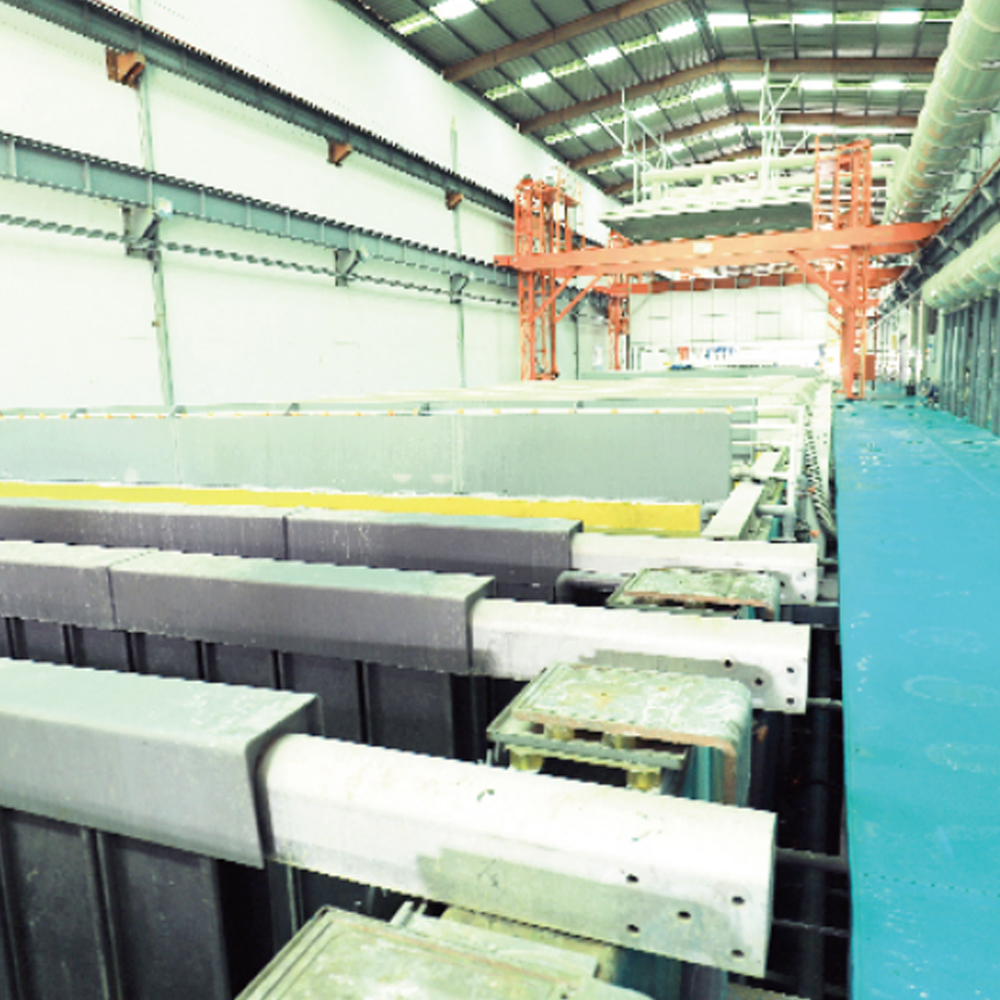

Aluminium Extrusion for Energy Storage Battery Pack New Energy Aluminum Extrusions Profiles

Aluminium Extrusion for Energy Storage Battery Pack New Energy Aluminum Extrusions Profiles -

Photovoltaic Mounting Bracket Aluminium Profiles New Energy Aluminum Extrusions Profiles

Photovoltaic Mounting Bracket Aluminium Profiles New Energy Aluminum Extrusions Profiles -

Car Roof Rack Aluminum Extrusion Profiles Automotive Aluminum Extrusion Profiles

Car Roof Rack Aluminum Extrusion Profiles Automotive Aluminum Extrusion Profiles -

Car Aluminum Pedals Profile Automotive Aluminum Extrusion Profiles

Car Aluminum Pedals Profile Automotive Aluminum Extrusion Profiles -

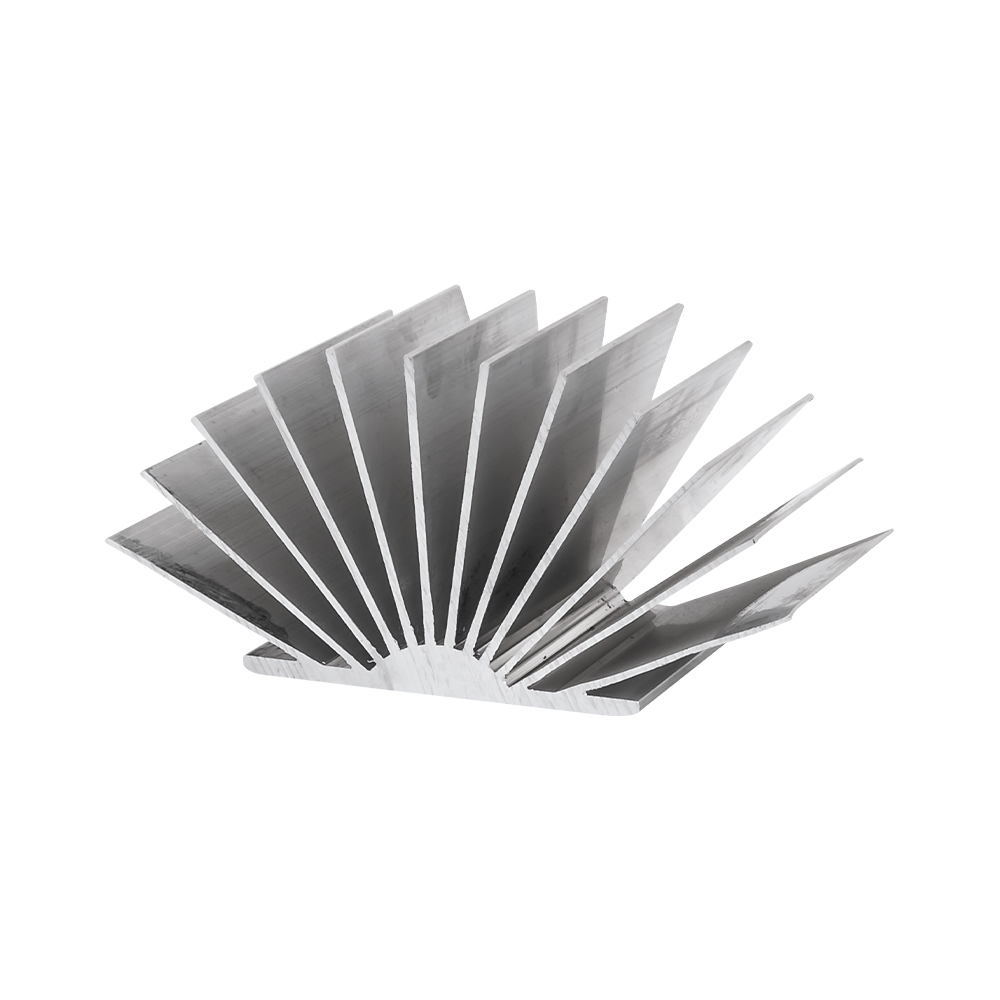

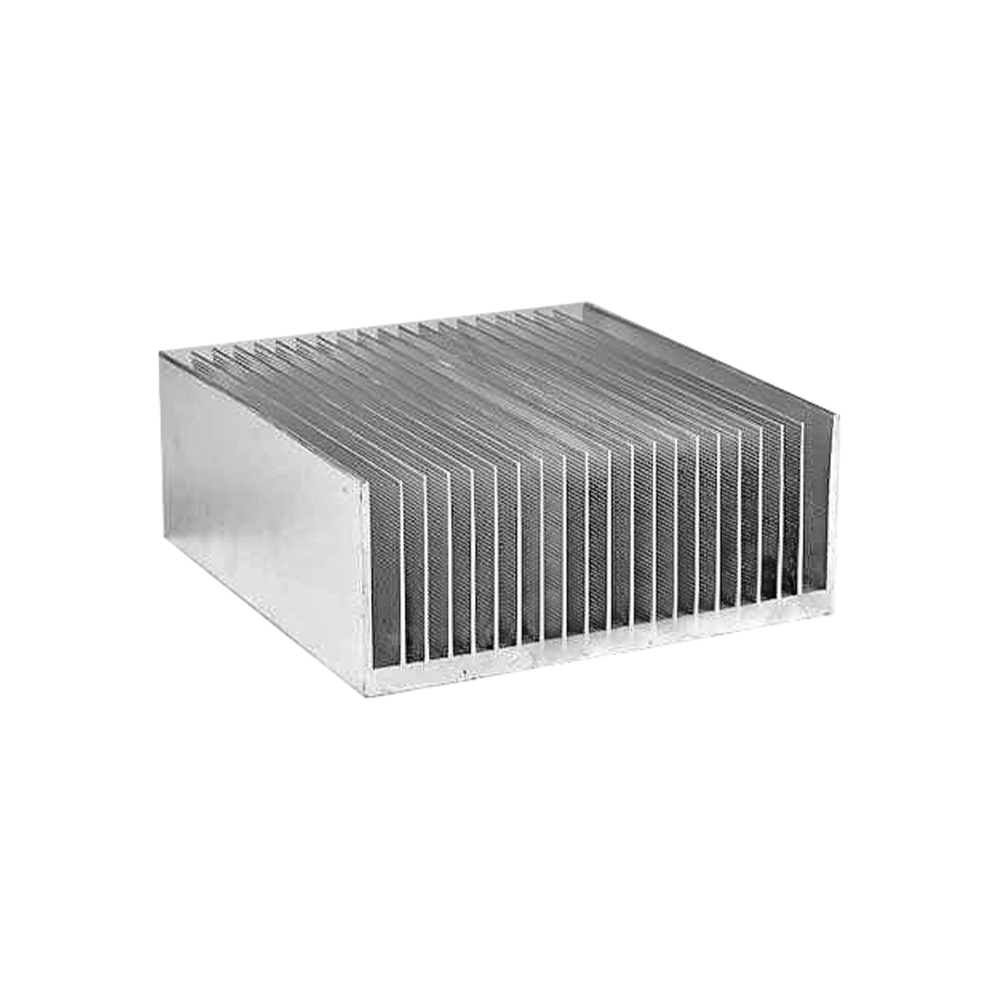

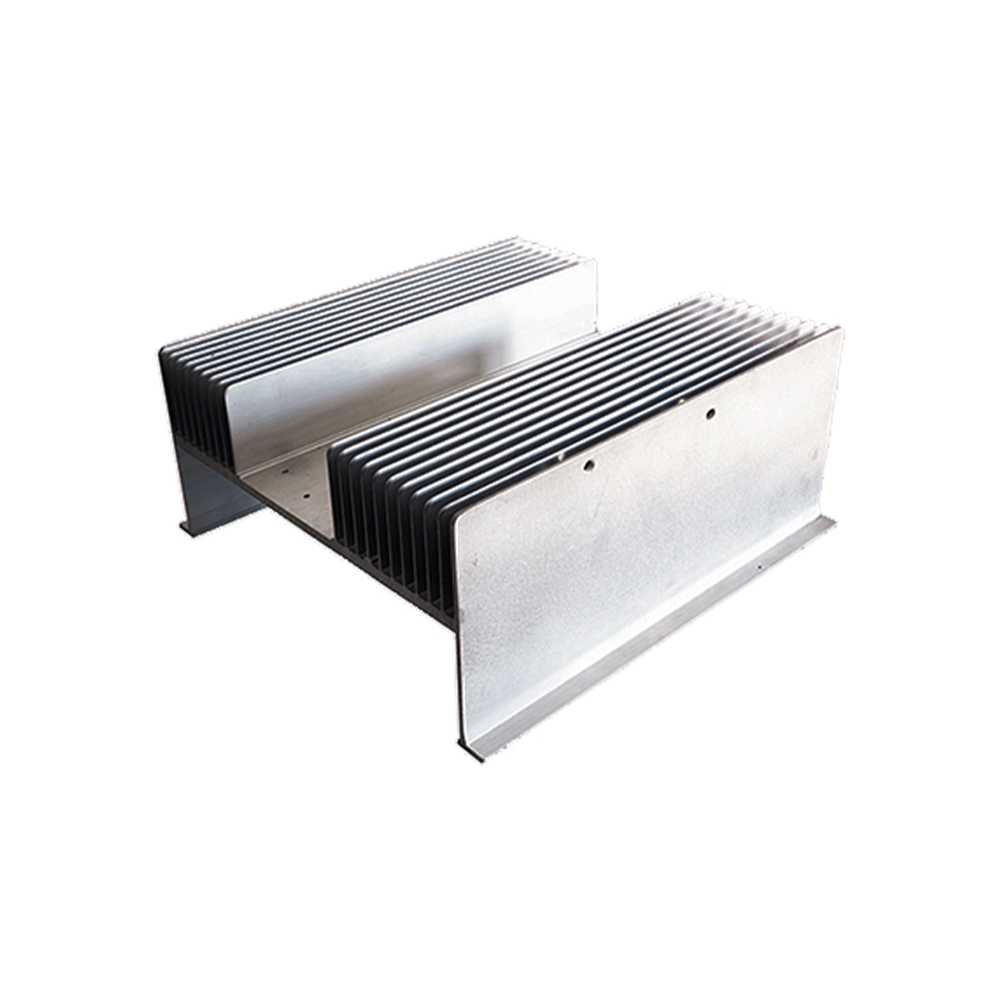

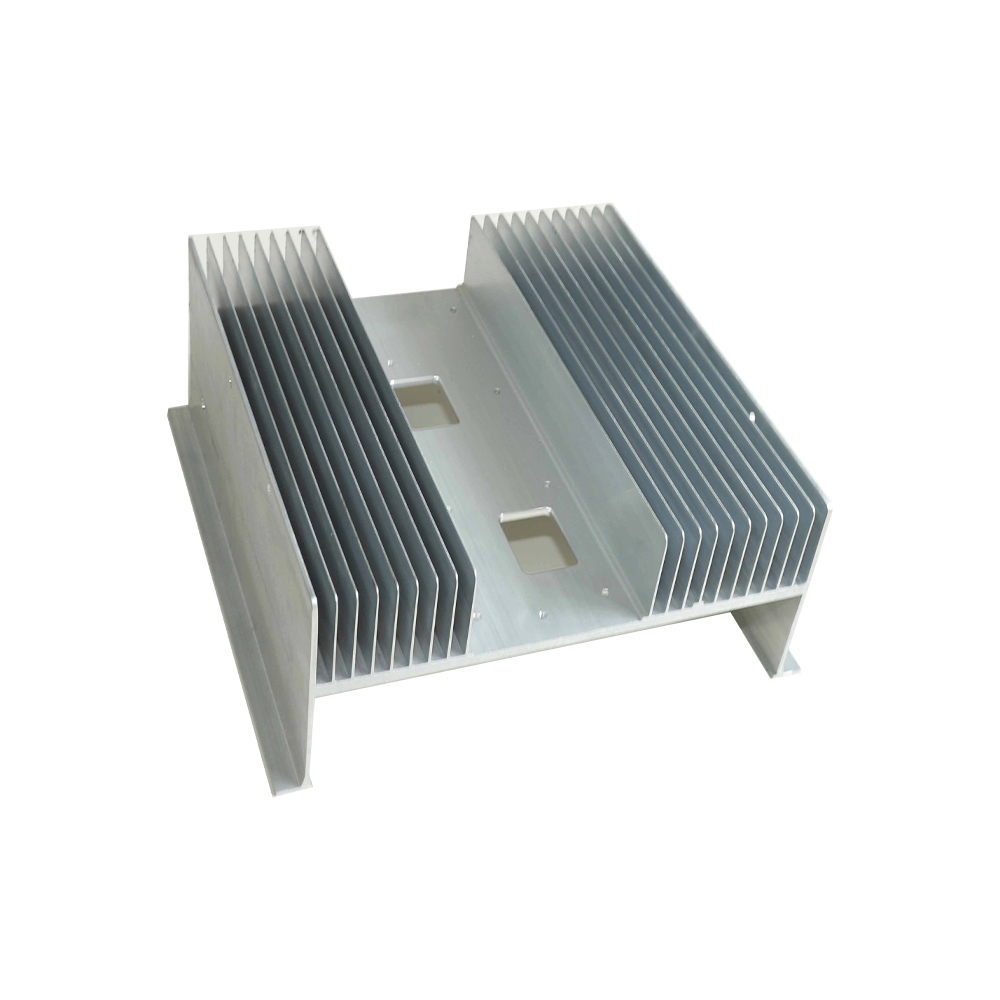

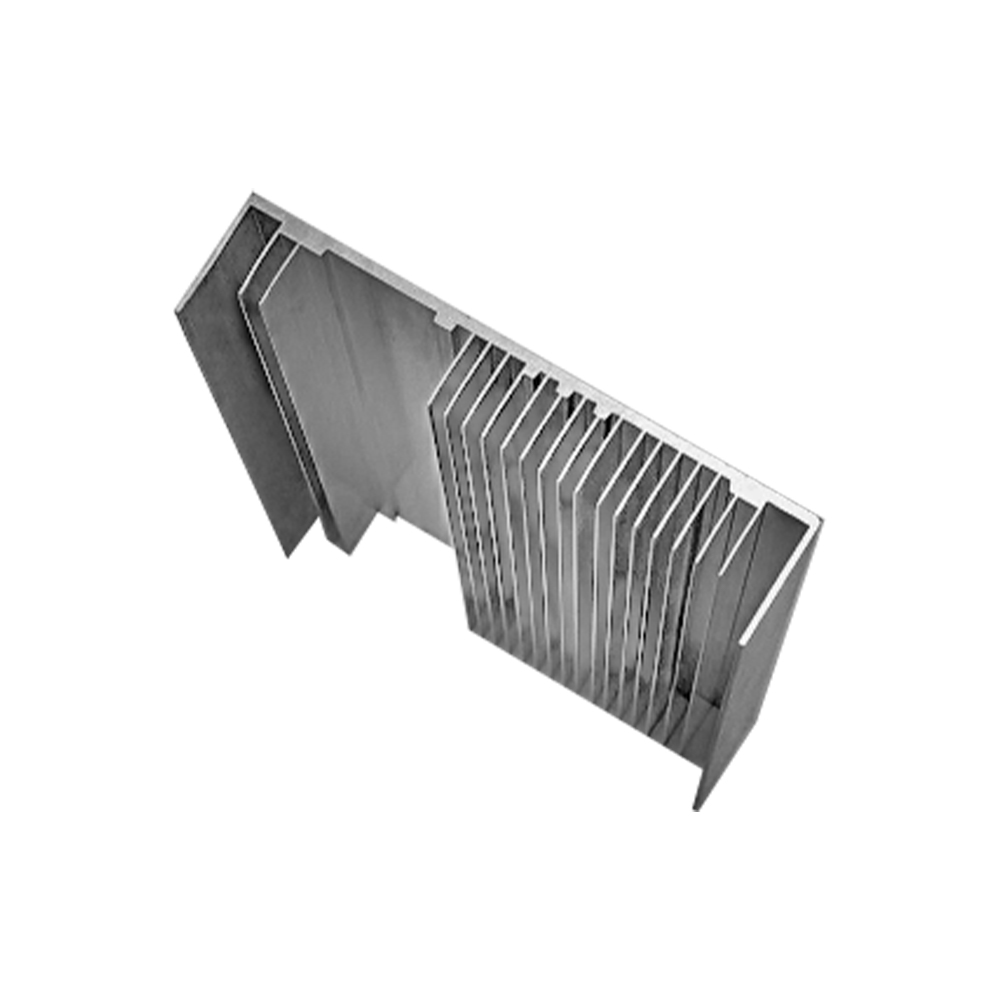

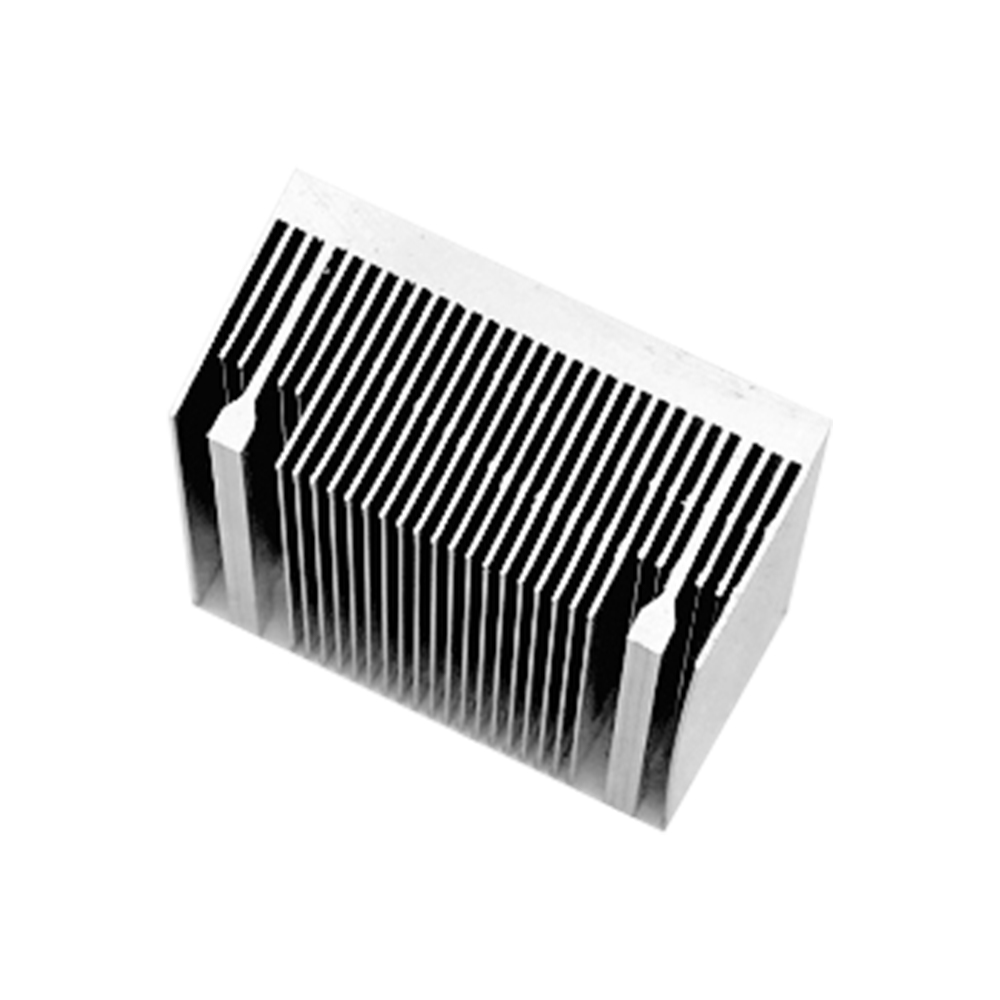

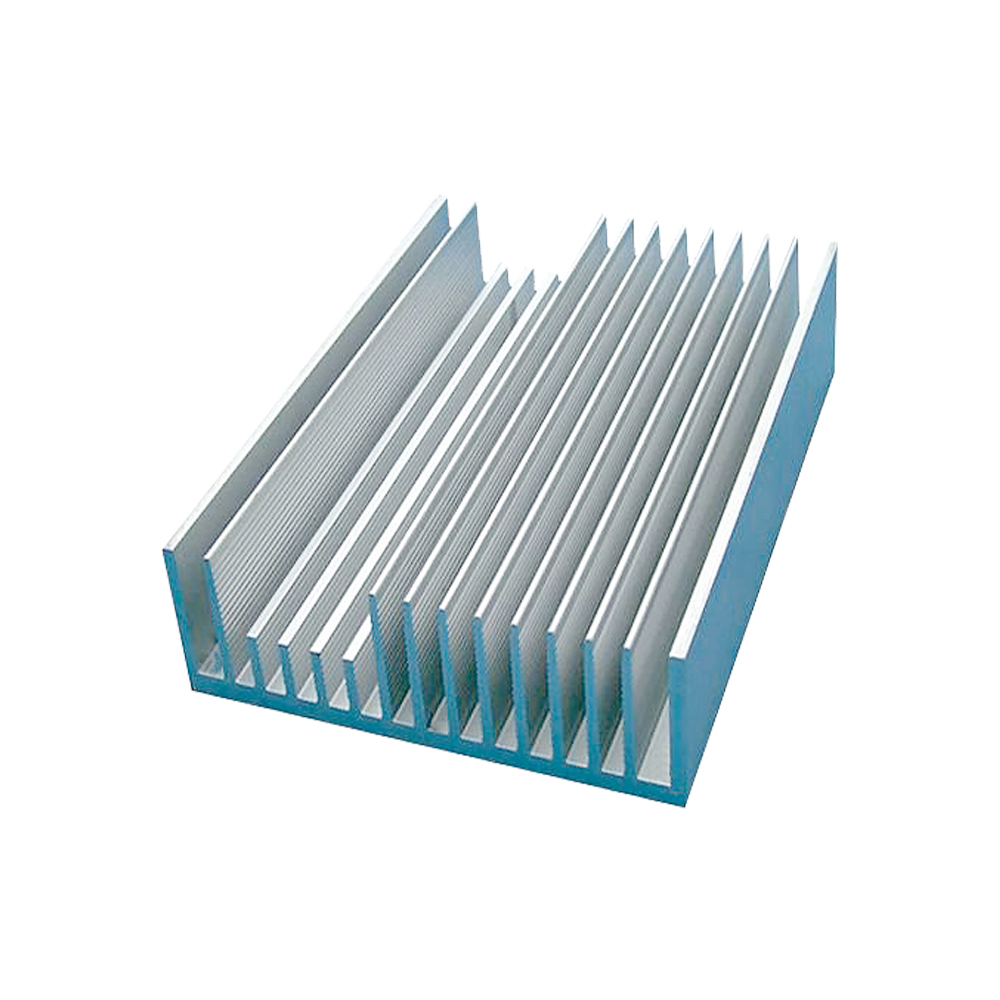

Aluminum Heat Sink Profiles Industrial Aluminum Extrusion Profiles

Aluminum Heat Sink Profiles Industrial Aluminum Extrusion Profiles -

Industrial Assembly Line Aluminum Profiles Industrial Aluminum Extrusion Profiles

Industrial Assembly Line Aluminum Profiles Industrial Aluminum Extrusion Profiles -

Aluminium Rail Transit Profiles Industrial Aluminum Extrusion Profiles

Aluminium Rail Transit Profiles Industrial Aluminum Extrusion Profiles -

Aluminum Fence Profiles Architectural Aluminum Extrusion Profiles

Aluminum Fence Profiles Architectural Aluminum Extrusion Profiles -

Scaffold Aluminum Profiles Architectural Aluminum Extrusion Profiles

Scaffold Aluminum Profiles Architectural Aluminum Extrusion Profiles -

Furniture Aluminium Profiles Architectural Aluminum Extrusion Profiles

Furniture Aluminium Profiles Architectural Aluminum Extrusion Profiles

Aluminum Heat Sink Profiles

We supply all kinds of motor shell profile, cylinder profile, motor shell profile, water-coolingmotor shell profile, all kinds of cylinder profile etc.

In today’s technology-driven world, effective thermal management is critical to ensuring the performance and longevity of electronic and industrial systems. Aluminum heat sink profiles stand at the forefront of this challenge, offering a reliable, cost-effective solution for dissipating heat efficiently. These components are engineered to meet the demands of modern applications, from LED lighting to automotive systems, by leveraging aluminum’s superior thermal conductivity and lightweight properties. As industries prioritize sustainability and performance, aluminum heat sinks have become indispensable in preventing overheating, optimizing device efficiency, and reducing energy costs.

Why Aluminum? Unmatched Material Advantages

Aluminum is the material of choice for heat sinks due to its unique combination of properties:

High Thermal Conductivity : Aluminum rapidly transfers heat away from sensitive components, ensuring consistent cooling.

Lightweight & Durable : Its low density reduces overall device weight without compromising structural integrity, ideal for portable electronics and automotive applications.

Corrosion Resistance : Naturally resistant to rust and environmental damage, aluminum heat sinks maintain performance in harsh conditions.

Eco-Friendly : Fully recyclable and requiring less energy to produce compared to other metals, aluminum aligns with global sustainability goals.

Innovative Design for Maximum Efficiency

The effectiveness of aluminum heat sink profiles lies in their precision-engineered designs:

Fins and Channels : Strategically placed fins increase surface area, accelerating heat dissipation into the surrounding air.

Customizable Geometry : Extrusion and machining processes allow for complex shapes, such as pin fins or cross-cut designs, tailored to specific airflow and space constraints.

Surface Treatments : Anodizing or powder coating enhances thermal emissivity and protects against wear, extending product lifespan.

These design innovations ensure optimal cooling even in compact or high-power systems, making aluminum heat sinks adaptable to evolving industry needs.

Applications Across Industries

Aluminum heat sinks are indispensable across diverse sectors:

LED Lighting : Prevents premature failure and color degradation in high-intensity lighting systems.

Power Electronics : Manages heat in inverters, converters, and motor drives to maintain efficiency.

Automotive : Cools electric vehicle batteries, chargers, and control units, supporting the shift to sustainable transportation.

Industrial Machinery : Protects high-performance equipment from overheating in factories and processing plants.

Their adaptability ensures reliable performance in both everyday consumer devices and mission-critical industrial systems.

Custom Solutions for Unique Needs

No two thermal challenges are identical. Manufacturers offer tailored aluminum heat sink profiles to meet specific requirements:

Size & Shape : Extrusion capabilities enable profiles of varying lengths, widths, and cross-sectional designs.

Fin Density & Spacing : Adjusted to match airflow conditions, whether natural convection or forced cooling.

Assembly Integration : Pre-drilled holes, brackets, or embedded heat pipes simplify installation into existing systems.

Aesthetic Finishes : Custom colors or textures align with brand identity or product design standards.

By collaborating closely with clients, manufacturers deliver solutions that address unique thermal, spatial, and operational demands.

Sustainable and Cost-Effective Thermal Management

Aluminum heat sinks provide long-term value through:

Energy Efficiency : Reduced cooling requirements lower power consumption, cutting operational costs.

Long Lifespan : Corrosion resistance and robust construction minimize replacement needs.

Scalable Production : Advanced extrusion and fabrication techniques ensure cost-effective mass production without sacrificing quality.

Recyclability : Aluminum’s circular lifecycle reduces waste and supports eco-conscious manufacturing practices.

Investing in aluminum heat sinks translates to lower total cost of ownership and a smaller environmental footprint.

Partner with Experts for Superior Thermal Solutions

As a leading manufacturer, we specialize in delivering aluminum heat sink profiles that combine innovation, quality, and sustainability. Our state-of-the-art facilities and engineering expertise ensure precision-crafted components tailored to your exact specifications. Whether standard or custom, our solutions are designed to enhance performance, reliability, and efficiency across industries.

Choose aluminum heat sink profiles—the smart, future-ready choice for thermal management.

-

In the manufacturing industry, advances in CNC machining technology cannot be made without the support of high-quality materials. Industrial aluminium profiles have become an indispensable material fo...

READ MORE -

With the growth of global demand for renewable energy, the application of industrial aluminium profiles in the field of new energy is promising. Especially in the field of solar and wind energy, alumi...

READ MORE -

Industrial aluminium profiles become new favourite as construction industry turns to green materials

The construction industry is progressively adopting environmentally friendly materials to reduce its impact on the environment. Industrial aluminium profiles are one of the preferred materials for gre...

READ MORE -

In recent years, automobile lightweight has attracted more and more attention, which is of extremely important significance to automobiles. Realize the lightweight of the car, the weight of the whole ...

READ MORE -

I believe that anyone who knows industrial aluminum profiles should know the industrial aluminum profile frame. Here I will give you a brief introduction: Industrial aluminum profile is also called fr...

READ MORE

English

English 日本語

日本語 한국어

한국어