Understanding Aluminium Extrusion Profiles

Aluminium extrusion profiles are a versatile solution for industries requiring lightweight, durable, and customizable components. By forcing aluminum through a shaped die, manufacturers can create profiles with precise dimensions and consistent quality. The resulting Aluminium Extrusion Profiles are widely used across construction, transportation, machinery, and renewable energy applications. Understanding the differences in strength, shape, and surface finish is essential for selecting the right profile for any project.

Strength Considerations in Aluminium Profiles

The strength of an aluminium extrusion profile depends on the alloy type, tempering process, and cross-sectional design. High-strength profiles are critical in structural applications such as building frames, rail transit components, and machinery supports.

Alloy Selection

Common aluminium alloys used in extrusion include 6063, 6061, and 6082. Each offers a balance of tensile strength, corrosion resistance, and formability. For example, 6061 profiles are suitable for load-bearing applications due to their higher mechanical strength, while 6063 is preferred for architectural designs requiring smooth surface finishes.

Profile Design

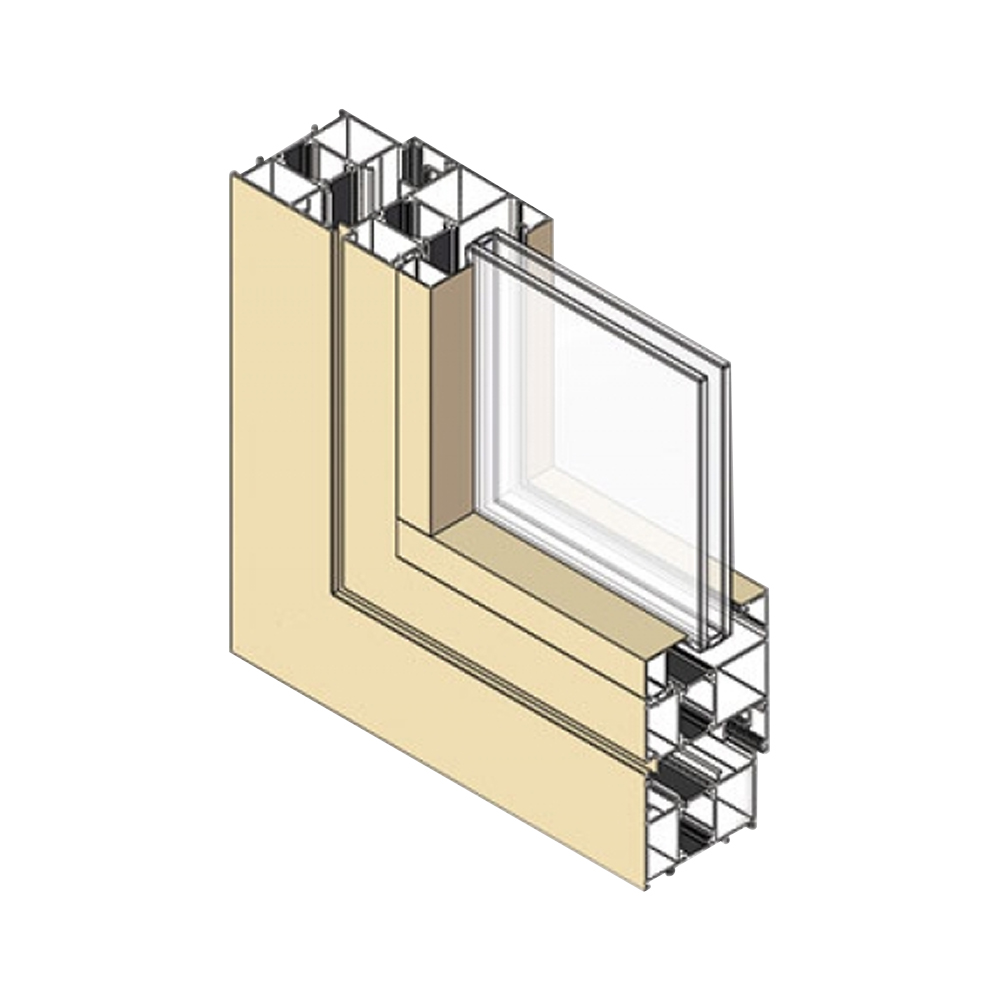

The cross-sectional shape of the profile significantly affects its strength. Thicker walls and reinforced corners increase rigidity, while hollow sections can reduce weight without compromising performance. Engineers often optimize profile design to meet specific mechanical requirements while minimizing material usage.

Shape Variations in Aluminium Extrusion Profiles

The shape of aluminium extrusion profiles can be customized to meet diverse functional and aesthetic requirements. Shapes range from simple rectangles and squares to complex multi-chambered or T-slot designs.

Standard vs. Custom Shapes

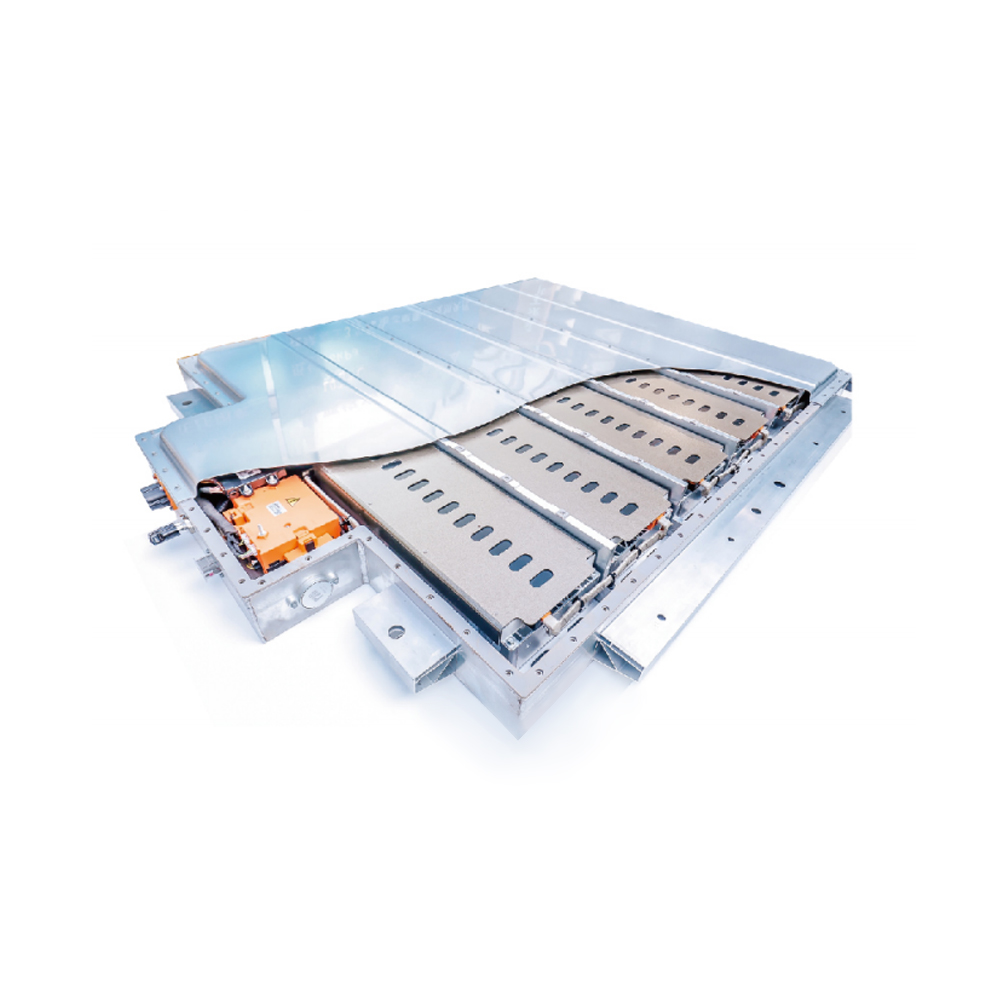

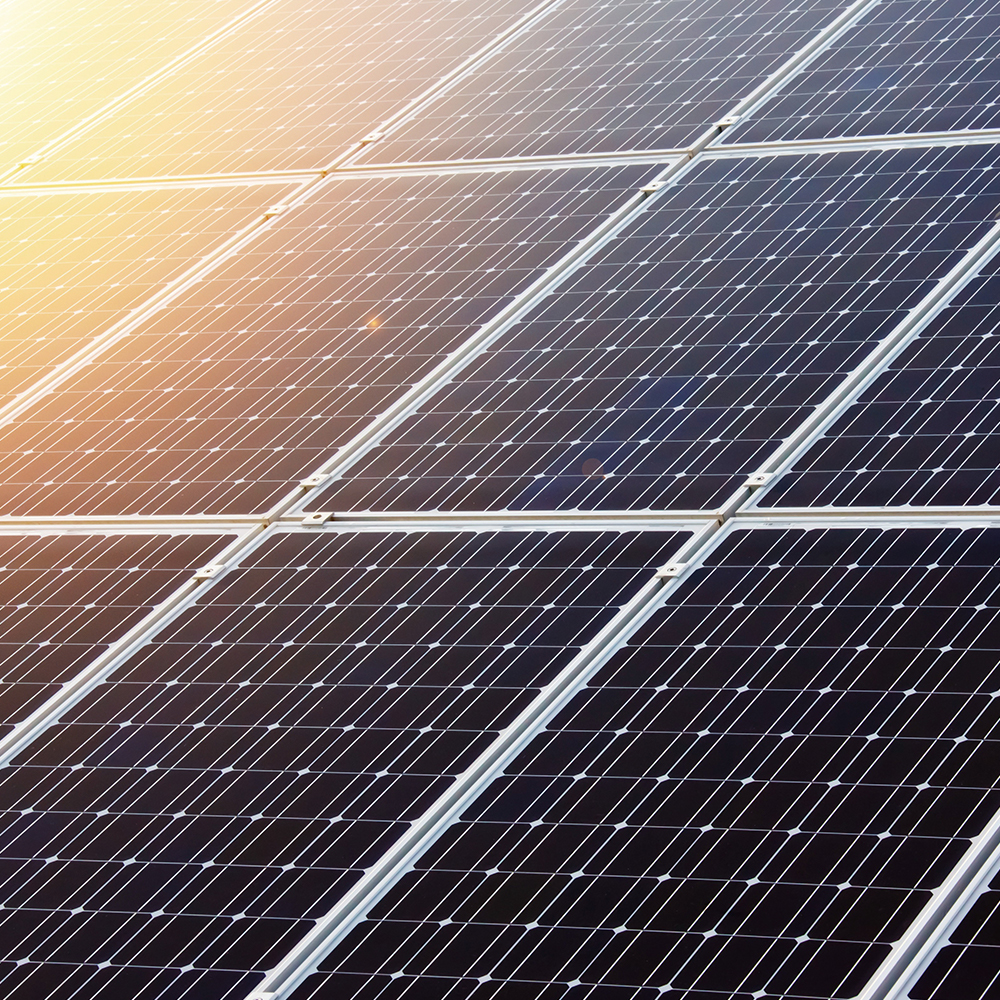

Standard profiles are widely available and suitable for general applications, while custom profiles are designed for specialized projects such as new energy vehicles, photovoltaic frames, and industrial machinery. Customization allows for precise integration with other components, improving assembly efficiency and structural performance.

T-Slot and Modular Designs

T-slot profiles and modular aluminium systems provide flexibility in construction and assembly. These profiles allow easy attachment of panels, fasteners, and accessories, making them ideal for automation equipment, workstations, and lightweight structural frameworks.

Surface Finish Options for Aluminium Profiles

Surface finish not only enhances aesthetics but also provides additional protection against corrosion and wear. Selecting the appropriate finish is crucial for both indoor and outdoor applications.

Anodizing

Anodized aluminium profiles feature a durable oxide layer that improves corrosion resistance and allows for a variety of color options. This finish is ideal for architectural applications and outdoor installations where long-term durability is required.

Powder Coating and PvDF Coatings

Powder-coated and PvDF-coated profiles provide enhanced weather resistance and color stability. Powder coating is commonly used for industrial equipment and structural profiles, while PvDF coatings offer superior UV and chemical resistance, making them suitable for solar panels and façade systems.

Comparing Aluminium Extrusion Profiles

The following table highlights key differences in strength, shape, and surface finish for common aluminium extrusion profiles:

| Profile Type | Strength Characteristics | Shape Features | Surface Finish Options |

| Standard Rectangular | Moderate tensile strength, suitable for general construction | Simple, uniform cross-section | Anodized, Powder Coated |

| T-Slot / Modular | High structural flexibility, suitable for adjustable frameworks | Channels for attachments and connectors | Anodized, PvDF, Powder Coated |

| Custom Complex Profiles | Optimized for specific load-bearing or mechanical requirements | Multi-chambered or asymmetric designs | Anodized, Powder Coated, PvDF |

Conclusion

Selecting the right aluminium extrusion profile requires careful consideration of strength, shape, and surface finish. Standard profiles provide reliable performance for general applications, while T-slot and custom designs enable greater flexibility and load optimization. Surface treatments further enhance durability and appearance. By understanding these factors, engineers and designers can choose Aluminium Extrusion Profiles that meet both functional and aesthetic requirements, supporting long-lasting and efficient projects across construction, transportation, and industrial applications.

English

English 日本語

日本語 한국어

한국어