The Importance of Aluminium Extrusion Profiles in Modern Vehicles

Aluminium extrusion profiles have become a fundamental component in the automotive and new energy vehicle industry. Their combination of lightweight properties, high strength, and design flexibility makes them ideal for improving vehicle efficiency, safety, and sustainability. Manufacturers, including leading Aluminium Profile Distributors, are increasingly leveraging advanced extrusion techniques to meet the specific needs of electric vehicles (EVs) and hybrid platforms.

Lightweighting and Vehicle Efficiency

Reducing vehicle weight is a primary goal for both conventional and new energy vehicles. Aluminium Extrusion Profiles offer a high strength-to-weight ratio, which allows automakers to replace heavier steel components without compromising structural integrity. This contributes to:

- Improved energy efficiency and extended driving range in EVs.

- Reduced fuel consumption and emissions in hybrid and traditional vehicles.

- Enhanced handling and performance due to lower vehicle mass.

Structural Applications in New Energy Vehicles

Aluminium profiles are widely used in EV chassis, body frames, crash structures, and battery enclosures. Their precise extrusion allows for uniform cross-sections and complex geometries that meet stringent mechanical and safety standards.

Chassis and Frame Components

High-strength Aluminium Extrusion Profiles form key structural elements, including vehicle side members, crossbeams, and subframes. Optimized profile shapes improve rigidity while minimizing weight, which is critical for battery-powered vehicles where efficiency is closely linked to overall mass.

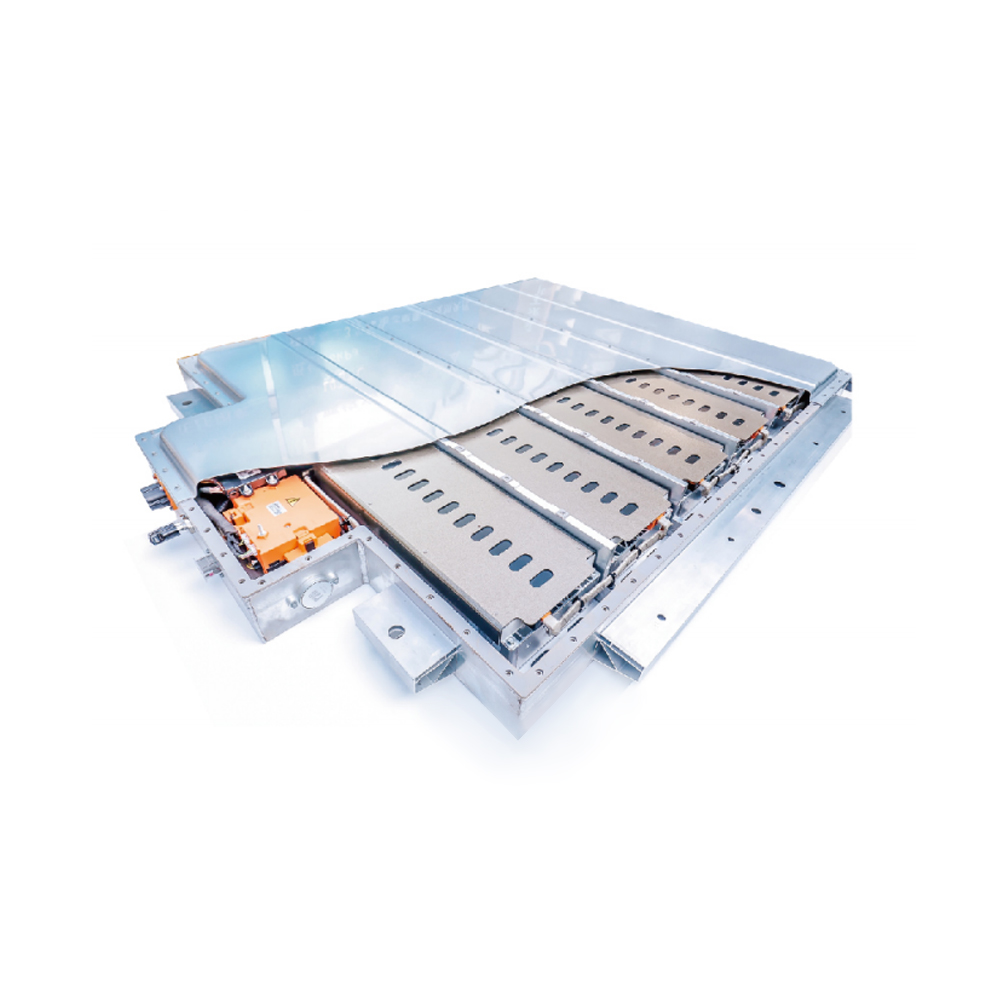

Battery Housings and Thermal Management

Aluminium Extrusion Profiles are commonly used in battery enclosures to provide protection and facilitate heat dissipation. Their thermal conductivity ensures stable battery temperatures, enhancing both safety and performance of electric vehicles.

Surface Finishes and Corrosion Resistance

The harsh environments that vehicles are exposed to make surface treatment critical. Aluminium Extrusion Profiles can be anodized, powder-coated, or treated with PvDF coatings to improve durability, UV resistance, and corrosion protection. These treatments are especially important for EVs and hybrid vehicles used in diverse climates.

Anodized Profiles

Anodizing produces a hard oxide layer on aluminium surfaces, enhancing scratch resistance and maintaining aesthetic appeal. This is widely used in visible structural and body components.

Powder Coating and PvDF Treatments

Powder coating and PvDF treatments provide superior corrosion and weather resistance, ideal for battery housings, exterior panels, and underbody components. These finishes maintain performance even under exposure to road salts, humidity, and UV radiation.

Comparing Aluminium Extrusion Profiles in Automotive Applications

Different profile designs and treatments are suited for specific automotive applications. The table below summarizes key types of Aluminium Extrusion Profiles used in vehicle structures and their benefits:

| Profile Type | Typical Application | Key Benefits | Surface Treatments |

| High-Strength Structural | Chassis, subframes, crash structures | High rigidity, lightweight, energy absorption | Anodized, Powder Coated |

| Battery Enclosure Profiles | Battery housings, thermal channels | Heat dissipation, protection, durability | PvDF, Powder Coated |

| Exterior and Interior Panels | Door frames, roof rails, trim | Aesthetic appeal, corrosion resistance, lightweight | Anodized, Powder Coated, PvDF |

Future Trends in Vehicle Aluminium Extrusions

The automotive industry is increasingly focused on electrification, sustainability, and modular design. Aluminium Extrusion Profiles will continue to play a critical role in these trends. Future developments include:

- Lightweight high-strength alloys for improved vehicle range and safety.

- More complex profile designs for integrated assembly and modularity.

- Enhanced surface treatments to meet extreme environmental and aesthetic requirements.

- Closer collaboration between Aluminium Profile Distributors and vehicle manufacturers for customized solutions.

Conclusion

Aluminium extrusion profiles are indispensable in the design and manufacturing of modern automotive and new energy vehicles. They provide the necessary balance of strength, weight reduction, and versatility while enabling innovative solutions for battery protection, chassis structures, and vehicle aesthetics. By leveraging advanced Aluminium Extrusion Profiles and collaborating with trusted Aluminium Profile Distributors, automakers can achieve higher efficiency, enhanced safety, and sustainable performance for the next generation of vehicles.

English

English 日本語

日本語 한국어

한국어