-

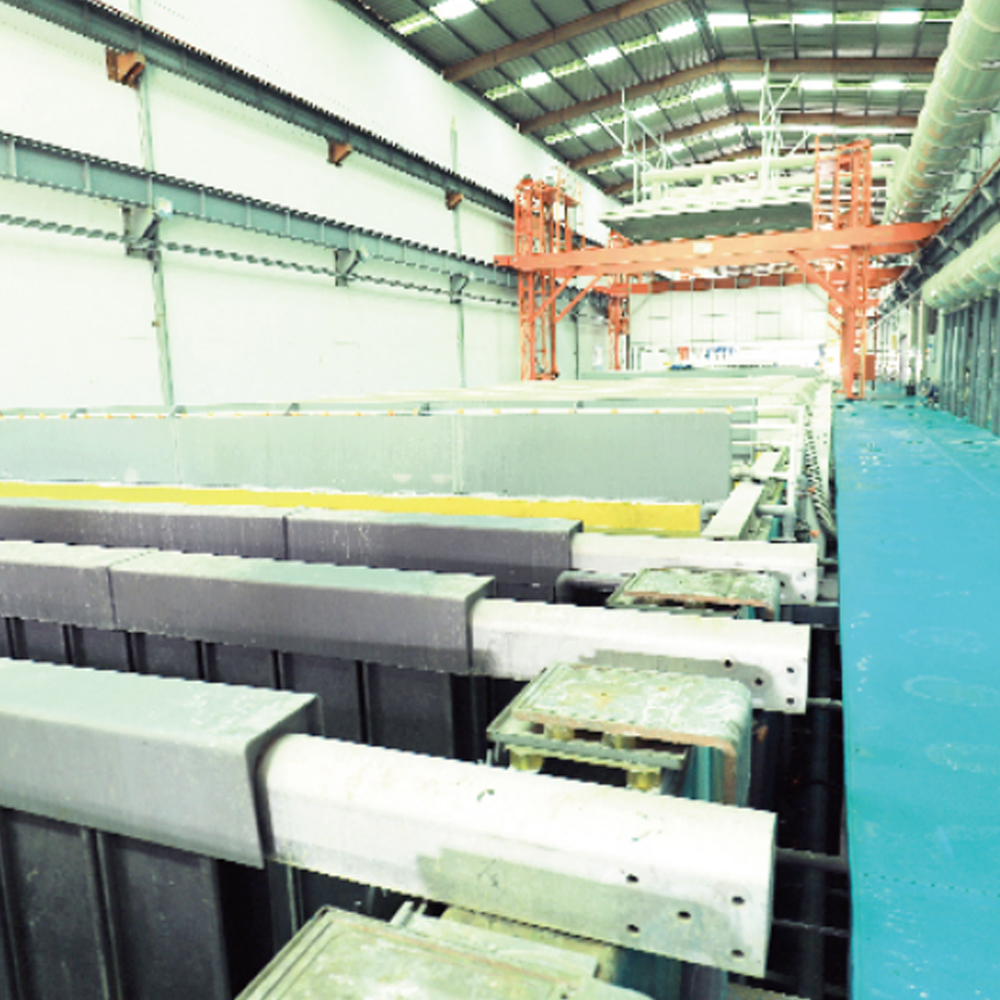

Aluminum Profiles Surface Treatment Aluminum Profiles Surface Treatment

Aluminum Profiles Surface Treatment Aluminum Profiles Surface Treatment -

Automotive Parts CNC Machining Industrial Automotive Parts Precision Machining

Automotive Parts CNC Machining Industrial Automotive Parts Precision Machining -

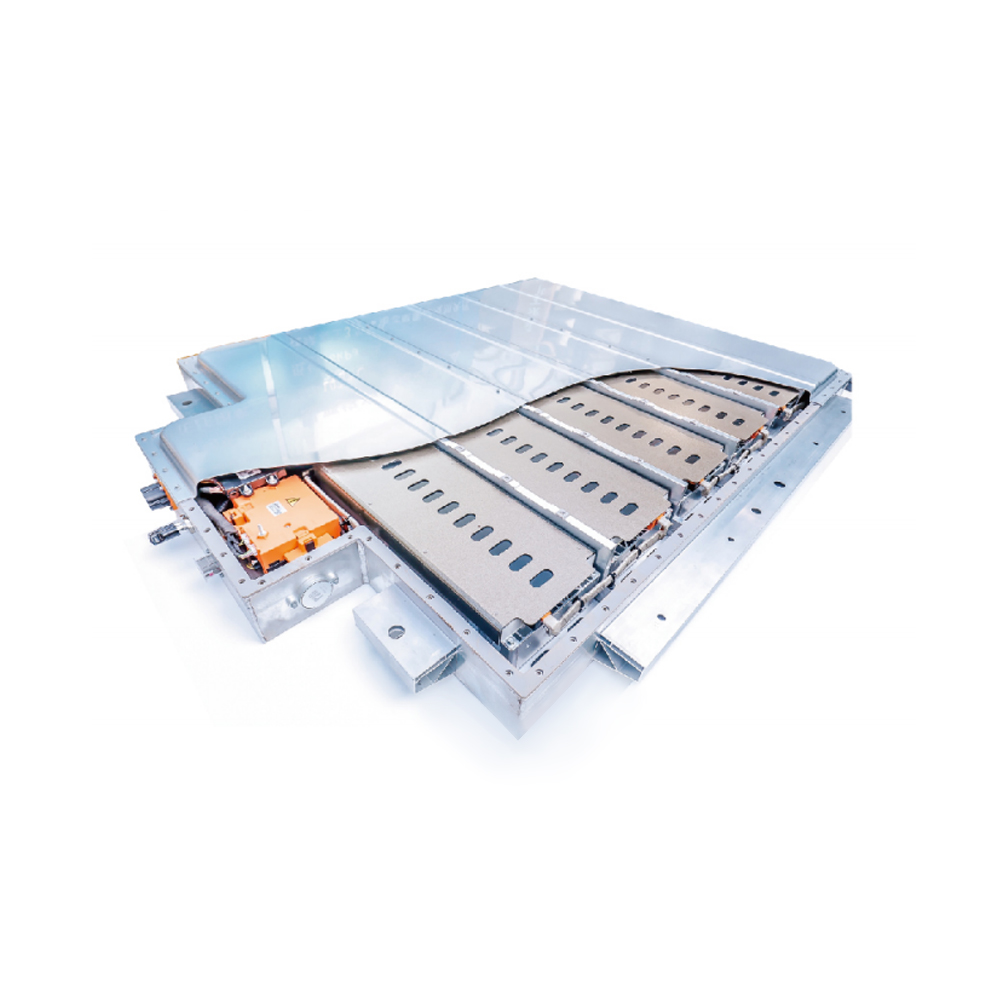

Aluminium Extrusion for Energy Storage Battery Pack New Energy Aluminum Extrusions Profiles

Aluminium Extrusion for Energy Storage Battery Pack New Energy Aluminum Extrusions Profiles -

Photovoltaic Mounting Bracket Aluminium Profiles New Energy Aluminum Extrusions Profiles

Photovoltaic Mounting Bracket Aluminium Profiles New Energy Aluminum Extrusions Profiles -

Car Roof Rack Aluminum Extrusion Profiles Automotive Aluminum Extrusion Profiles

Car Roof Rack Aluminum Extrusion Profiles Automotive Aluminum Extrusion Profiles -

Car Aluminum Pedals Profile Automotive Aluminum Extrusion Profiles

Car Aluminum Pedals Profile Automotive Aluminum Extrusion Profiles -

Aluminum Heat Sink Profiles Industrial Aluminum Extrusion Profiles

Aluminum Heat Sink Profiles Industrial Aluminum Extrusion Profiles -

Industrial Assembly Line Aluminum Profiles Industrial Aluminum Extrusion Profiles

Industrial Assembly Line Aluminum Profiles Industrial Aluminum Extrusion Profiles -

Aluminium Rail Transit Profiles Industrial Aluminum Extrusion Profiles

Aluminium Rail Transit Profiles Industrial Aluminum Extrusion Profiles -

Aluminum Fence Profiles Architectural Aluminum Extrusion Profiles

Aluminum Fence Profiles Architectural Aluminum Extrusion Profiles -

Scaffold Aluminum Profiles Architectural Aluminum Extrusion Profiles

Scaffold Aluminum Profiles Architectural Aluminum Extrusion Profiles -

Furniture Aluminium Profiles Architectural Aluminum Extrusion Profiles

Furniture Aluminium Profiles Architectural Aluminum Extrusion Profiles

Car Roof Rack Aluminum Extrusion Profiles

Crafted for durability, versatility, and style, Car Roof Rack Aluminum Extrusion Profiles redefine vehicle storage. Designed for manufacturers seeking high-performance solutions, these profiles combine advanced engineering with sleek aesthetics. Ideal for outdoor enthusiasts and commercial users alike, they offer unmatched strength, weather resistance, and customization.

1. Superior Material & Structural Design

High-Strength Aluminum Alloy

Manufactured from premium-grade 6063-T5 aluminum, these profiles deliver exceptional tensile strength (≥160 MPa) while weighing 30% less than steel alternatives.

Optimized wall thickness (1.5–3.0mm) ensures load-bearing capacity up to 150kg, meeting ISO 11154 dynamic load standards.

Corrosion Resistance

Anodized surface treatment (10–15μm thickness) enhances oxidation and salt-spray resistance, ensuring longevity in harsh environments.

Passes 1,000-hour neutral salt spray testing (ASTM B117), ideal for coastal or winter road conditions.

Lightweight Efficiency

Reduces vehicle fuel consumption by 2–5% compared to steel racks, aligning with global lightweighting trends.

2. Modular Customization for Diverse Applications

Flexible Profile Geometry

T-slot, box-beam, and open-channel designs support seamless integration with third-party accessories (e.g., Thule, Yakima).

Customizable cross-sectional shapes (rectangular, elliptical, aerodynamic) to match vehicle roof contours.

Accessory Compatibility

Pre-drilled mounting holes and standardized interfaces (M6/M8 threads) enable quick assembly of bike racks, cargo boxes, or ladder holders.

Aesthetic Adaptability

Matte/satin finishes in silver, black, or custom RAL colors to complement vehicle aesthetics.

Smooth surface profiles minimize wind noise (tested at ≤65 dB at 100 km/h).

3. Cost-Effective Manufacturing & Scalability

High-Yield Production

600–1,200-ton extrusion presses achieve tight tolerances (±0.1mm) for consistent quality.

Batch orders from 500–50,000 meters supported with 3–5 week lead times.

Low Tooling Costs

Modular die designs reduce upfront tooling investment by 40% vs. monolithic dies.

Recyclable scrap material lowers production waste.

Global Compliance

Meets EN 755-2 (alloy composition), RoHS, and REACH regulations for seamless export.

4. End-User Benefits Driving Demand

All-Weather Reliability

Withstands -40°C to +80°C temperature ranges, maintaining structural integrity in extreme climates.

Quick Installation

Clamp-on or track-mounted systems require no drilling for most vehicles, reducing labor costs.

Low Maintenance

Self-cleaning surfaces resist dirt buildup; periodic rinsing with water suffices for upkeep.

Why Partner with Us?

As a leading aluminum extrusion manufacturer, we deliver precision-engineered roof rack profiles that balance performance, cost, and aesthetics. Elevate your product lineup with extrusions built to exceed expectations—contact us today for samples or volume pricing!

-

In the manufacturing industry, advances in CNC machining technology cannot be made without the support of high-quality materials. Industrial aluminium profiles have become an indispensable material fo...

READ MORE -

With the growth of global demand for renewable energy, the application of industrial aluminium profiles in the field of new energy is promising. Especially in the field of solar and wind energy, alumi...

READ MORE -

Industrial aluminium profiles become new favourite as construction industry turns to green materials

The construction industry is progressively adopting environmentally friendly materials to reduce its impact on the environment. Industrial aluminium profiles are one of the preferred materials for gre...

READ MORE -

In recent years, automobile lightweight has attracted more and more attention, which is of extremely important significance to automobiles. Realize the lightweight of the car, the weight of the whole ...

READ MORE -

I believe that anyone who knows industrial aluminum profiles should know the industrial aluminum profile frame. Here I will give you a brief introduction: Industrial aluminum profile is also called fr...

READ MORE

English

English 日本語

日本語 한국어

한국어