-

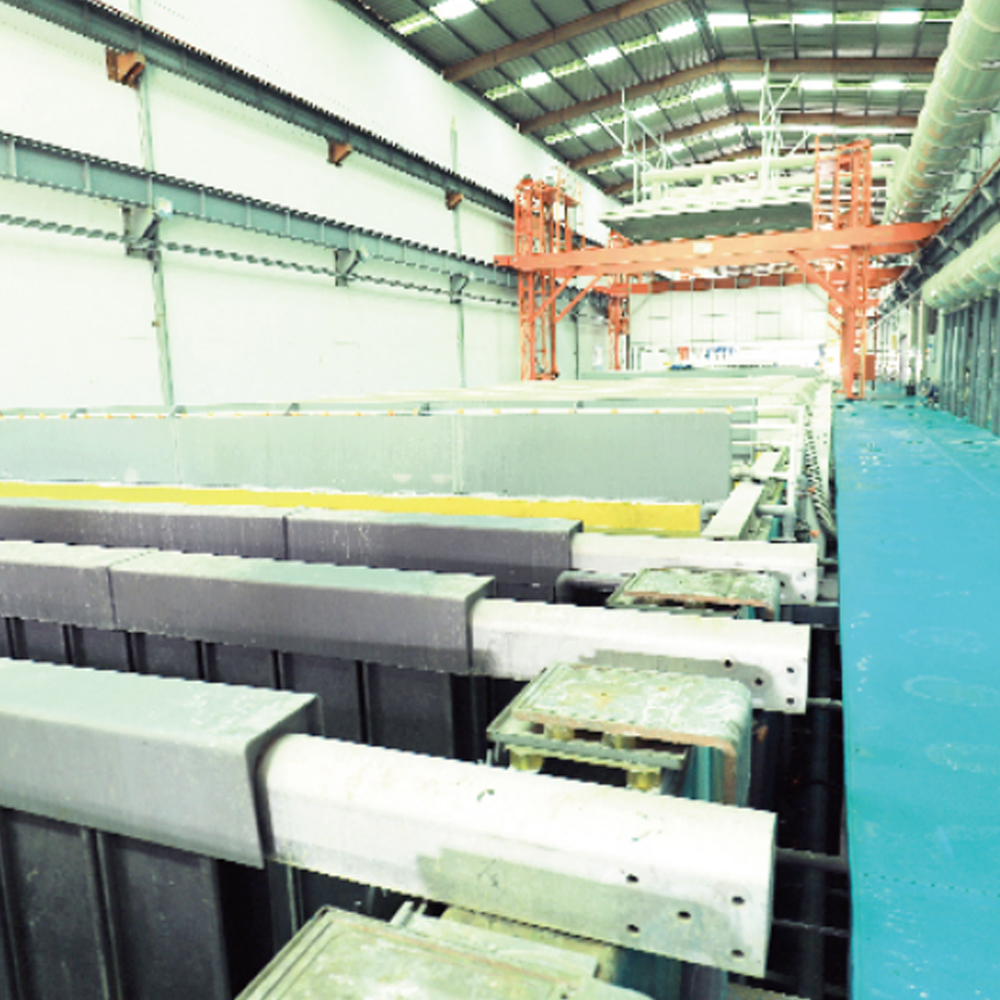

Aluminum Profiles Surface Treatment Aluminum Profiles Surface Treatment

Aluminum Profiles Surface Treatment Aluminum Profiles Surface Treatment -

Automotive Parts CNC Machining Industrial Automotive Parts Precision Machining

Automotive Parts CNC Machining Industrial Automotive Parts Precision Machining -

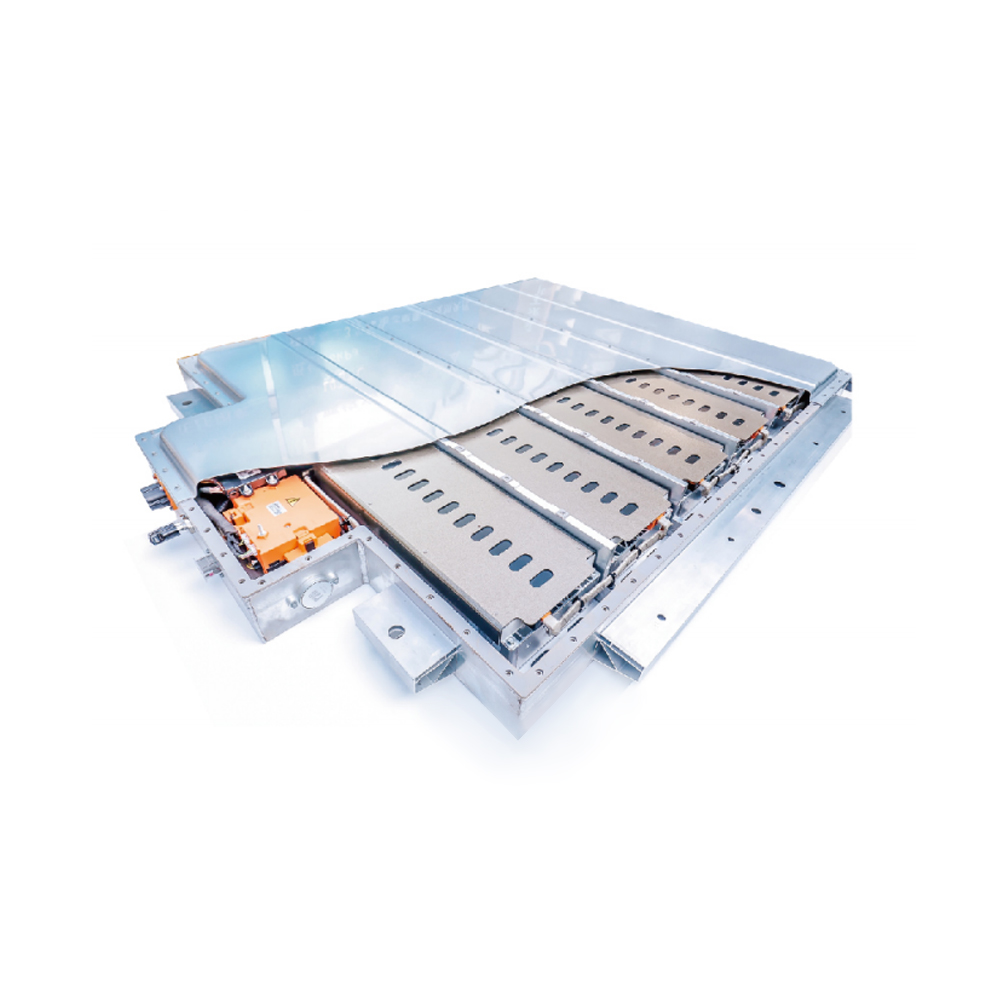

Aluminium Extrusion for Energy Storage Battery Pack New Energy Aluminum Extrusions Profiles

Aluminium Extrusion for Energy Storage Battery Pack New Energy Aluminum Extrusions Profiles -

Photovoltaic Mounting Bracket Aluminium Profiles New Energy Aluminum Extrusions Profiles

Photovoltaic Mounting Bracket Aluminium Profiles New Energy Aluminum Extrusions Profiles -

Car Roof Rack Aluminum Extrusion Profiles Automotive Aluminum Extrusion Profiles

Car Roof Rack Aluminum Extrusion Profiles Automotive Aluminum Extrusion Profiles -

Car Aluminum Pedals Profile Automotive Aluminum Extrusion Profiles

Car Aluminum Pedals Profile Automotive Aluminum Extrusion Profiles -

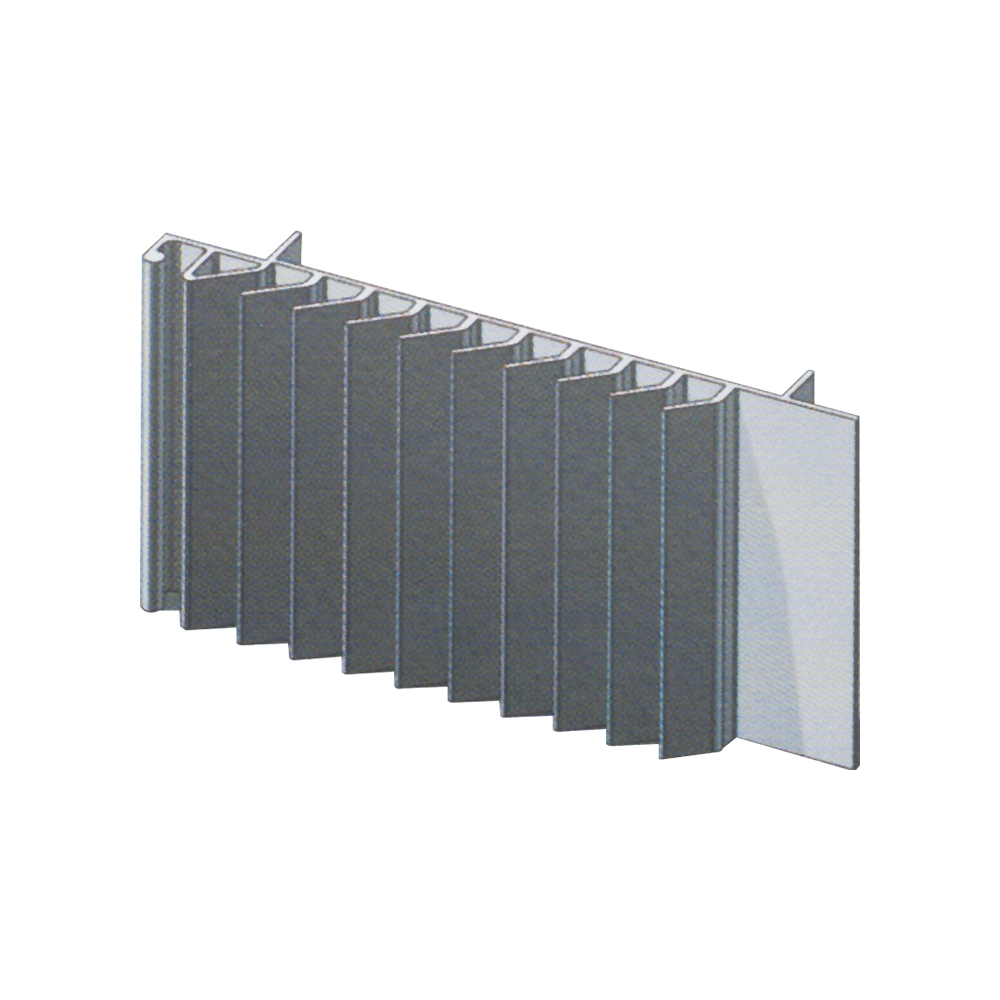

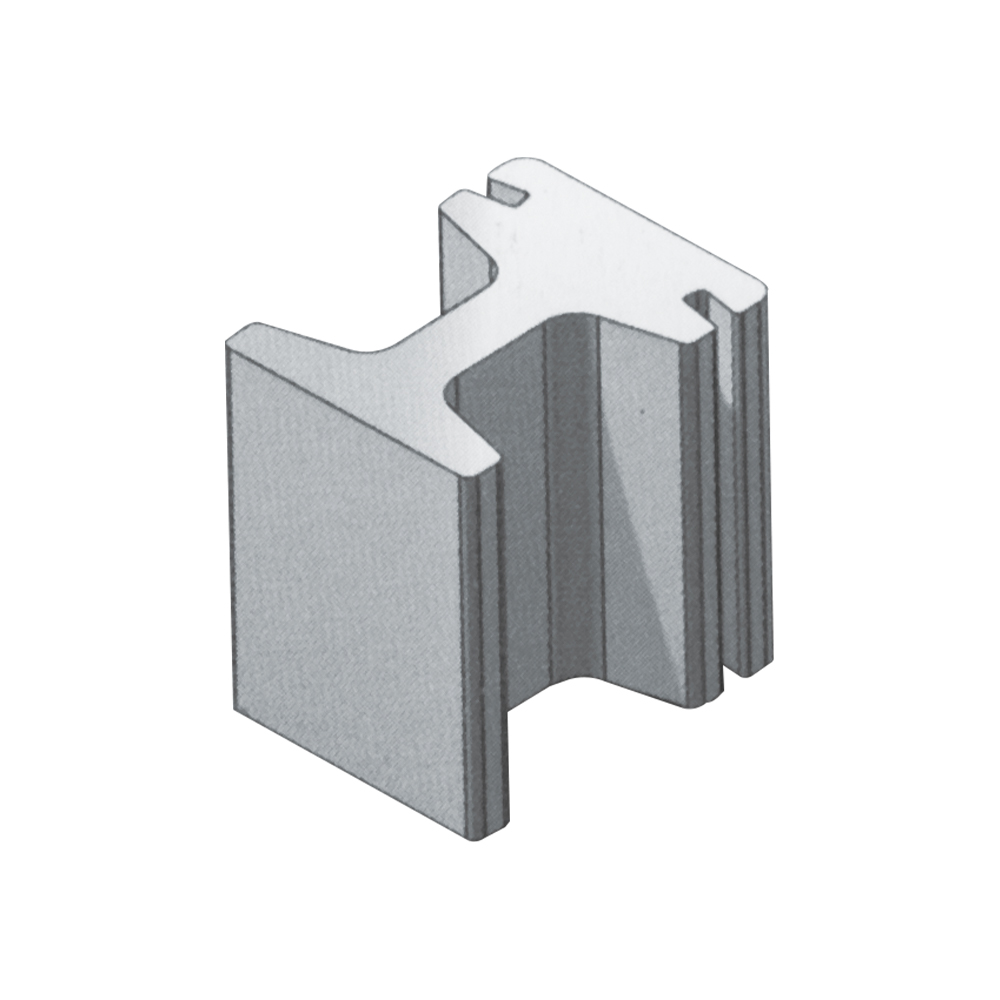

Aluminum Heat Sink Profiles Industrial Aluminum Extrusion Profiles

Aluminum Heat Sink Profiles Industrial Aluminum Extrusion Profiles -

Industrial Assembly Line Aluminum Profiles Industrial Aluminum Extrusion Profiles

Industrial Assembly Line Aluminum Profiles Industrial Aluminum Extrusion Profiles -

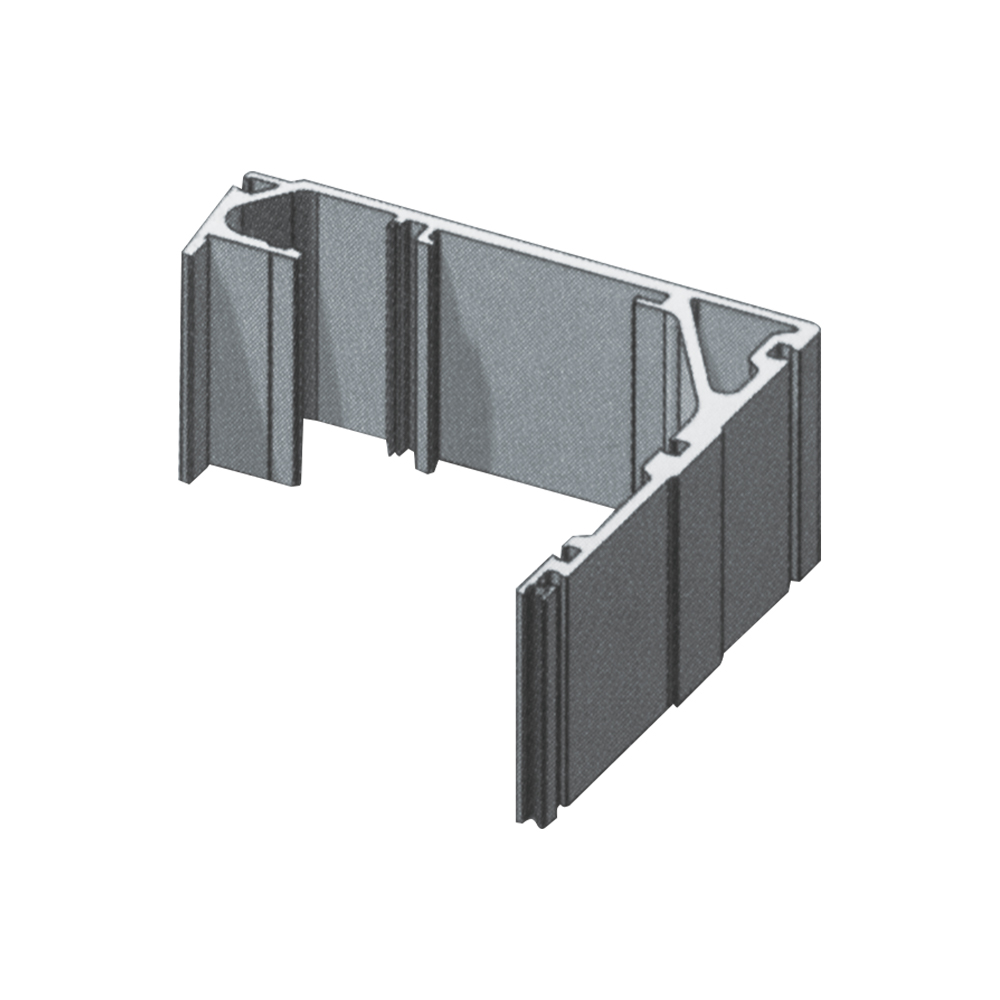

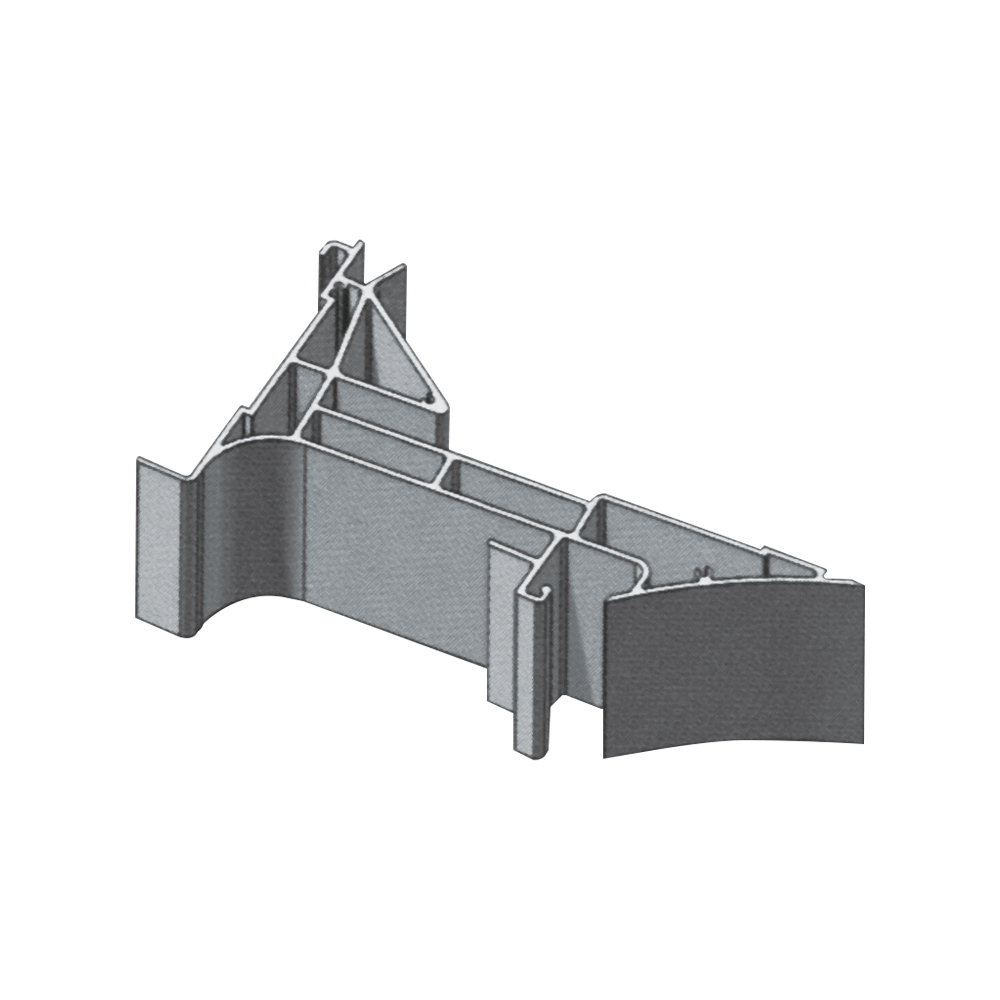

Aluminium Rail Transit Profiles Industrial Aluminum Extrusion Profiles

Aluminium Rail Transit Profiles Industrial Aluminum Extrusion Profiles -

Aluminum Fence Profiles Architectural Aluminum Extrusion Profiles

Aluminum Fence Profiles Architectural Aluminum Extrusion Profiles -

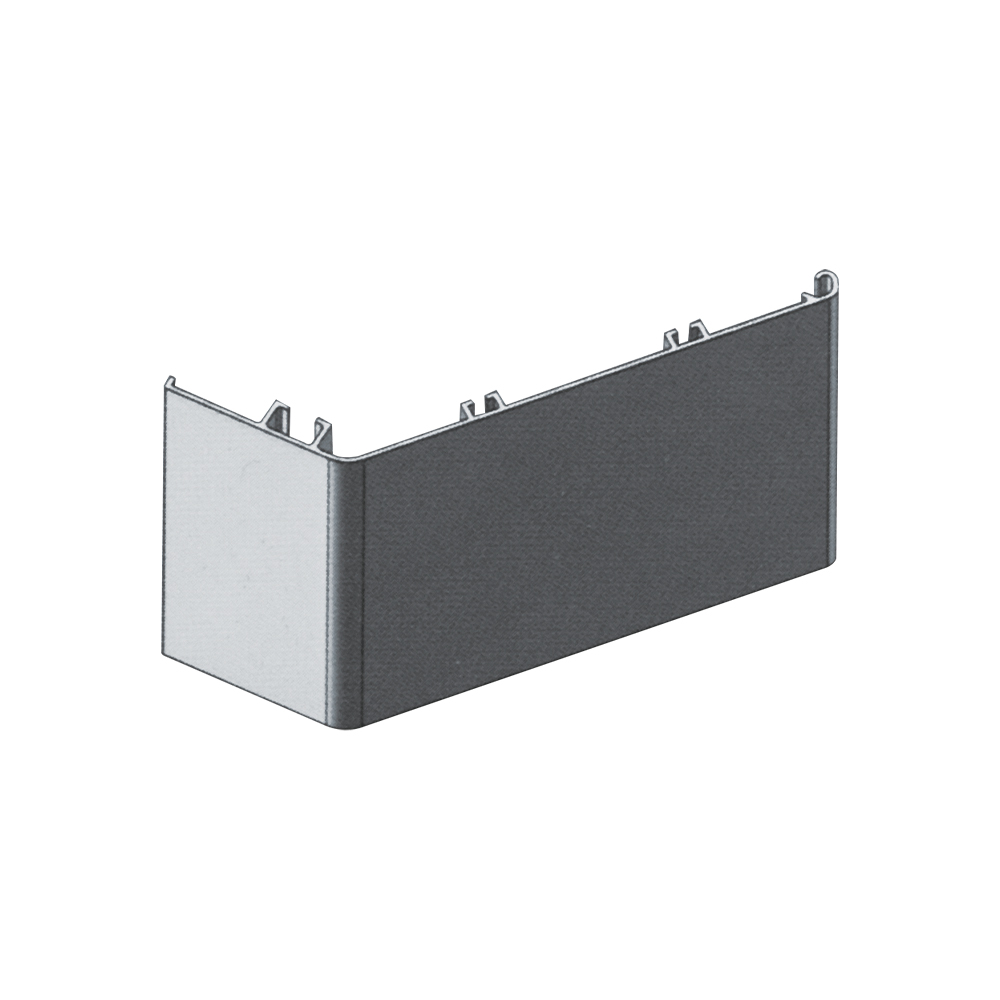

Scaffold Aluminum Profiles Architectural Aluminum Extrusion Profiles

Scaffold Aluminum Profiles Architectural Aluminum Extrusion Profiles -

Furniture Aluminium Profiles Architectural Aluminum Extrusion Profiles

Furniture Aluminium Profiles Architectural Aluminum Extrusion Profiles

Aluminium Rail Transit Profiles

High-speed train conductor rail, door motor beam profile, grating profile, shielded gatepanel, luggage rack etc.

Aluminum Rail Transit Profiles are engineered to redefine modern rail systems, combining cutting-edge design with unmatched performance. As the backbone of next-generation transportation, these profiles address critical challenges such as energy consumption, maintenance costs, and environmental impact. By integrating advanced material science with practical functionality, aluminum profiles emerge as the ultimate solution for rail operators seeking reliability, efficiency, and sustainability.

Lightweight Strength: Redefining Efficiency and Safety

Aluminum’s exceptional strength-to-weight ratio transforms rail infrastructure. Unlike traditional materials like steel, aluminum reduces the overall weight of train carriages, tracks, and support structures without compromising structural integrity. This lightweight design lowers energy consumption, enabling trains to operate with greater fuel efficiency or extended battery life in electric systems. Reduced weight also minimizes wear on tracks and components, slashing maintenance costs and downtime. For passenger safety, aluminum’s energy-absorbing properties enhance crashworthiness, while its rigidity ensures stable performance under dynamic loads. From high-speed trains to urban metro systems, aluminum profiles optimize both operational efficiency and safety standards.

Corrosion Resistance: Durability in Harsh Environments

Rail systems face relentless exposure to moisture, temperature fluctuations, and pollutants. Aluminum’s natural oxide layer provides superior corrosion resistance, ensuring longevity even in coastal, industrial, or chemically treated environments. Unlike steel, which requires frequent repainting or treatments, aluminum maintains its integrity over decades, reducing lifecycle costs. This durability extends to infrastructure components like station frameworks, walkways, and signaling systems, where rust-free performance is critical. For operators, this means fewer replacements, lower labor expenses, and uninterrupted service reliability—a critical advantage in demanding climates.

Precision Engineering: Streamlined Fabrication and Installation

Aluminum profiles are designed for seamless integration into rail projects. Their malleability allows for complex extrusions, enabling custom shapes that meet specific structural or aesthetic needs—from aerodynamic carriage designs to modular station frameworks. Advanced fabrication techniques ensure tight tolerances, while compatibility with welding, riveting, or adhesive bonding simplifies assembly. Prefabricated components reduce on-site construction time, minimizing disruptions to active rail networks. For contractors, this translates to faster project completion, reduced labor costs, and enhanced scalability for future expansions.

Thermal Conductivity: Enhancing Passenger Comfort

Aluminum’s high thermal conductivity plays a pivotal role in climate control. In train interiors, it dissipates heat efficiently, reducing reliance on energy-intensive HVAC systems. For infrastructure, aluminum components in stations or tunnels help regulate temperature extremes, mitigating the risk of track deformation or ice accumulation. This thermal efficiency not only improves passenger comfort but also safeguards operational continuity in harsh weather conditions. By maintaining stable environmental conditions, aluminum profiles contribute to smoother rides and reduced mechanical stress on critical systems.

Sustainability: Pioneering Green Mobility

As global rail networks strive for net-zero goals, aluminum emerges as a cornerstone of sustainable transit. Its recyclability—without degradation in quality—aligns with circular economy principles, reducing waste and resource consumption. Lightweighting directly cuts carbon emissions by lowering energy use per passenger mile. Additionally, aluminum’s longevity curbs the environmental footprint of frequent replacements. For eco-conscious operators, adopting aluminum profiles demonstrates a commitment to decarbonization while meeting regulatory and public expectations for greener infrastructure.

Conclusion:

Aluminum Rail Transit Profiles stand at the intersection of performance, economy, and sustainability. Their ability to enhance safety, reduce costs, and support environmental goals positions them as indispensable to modern rail systems. Whether revolutionizing high-speed rail networks, urban metros, or freight logistics, aluminum empowers operators to meet today’s challenges while future-proofing infrastructure for generations. In the race toward smarter, cleaner transportation, aluminum isn’t just a material—it’s the track to tomorrow.

-

In the manufacturing industry, advances in CNC machining technology cannot be made without the support of high-quality materials. Industrial aluminium profiles have become an indispensable material fo...

READ MORE -

With the growth of global demand for renewable energy, the application of industrial aluminium profiles in the field of new energy is promising. Especially in the field of solar and wind energy, alumi...

READ MORE -

Industrial aluminium profiles become new favourite as construction industry turns to green materials

The construction industry is progressively adopting environmentally friendly materials to reduce its impact on the environment. Industrial aluminium profiles are one of the preferred materials for gre...

READ MORE -

In recent years, automobile lightweight has attracted more and more attention, which is of extremely important significance to automobiles. Realize the lightweight of the car, the weight of the whole ...

READ MORE -

I believe that anyone who knows industrial aluminum profiles should know the industrial aluminum profile frame. Here I will give you a brief introduction: Industrial aluminum profile is also called fr...

READ MORE

English

English 日本語

日本語 한국어

한국어