In the manufacturing industry, advances in CNC machining technology cannot be made without the support of high-quality materials. Industrial aluminium profiles have become an indispensable material fo...

READ MOREAluminium Deep Processing Services

Aluminium deep processing services transform raw aluminium into high-value components and products tailored to meet diverse industry demands. Combining advanced engineering, cutting-edge technology, and meticulous craftsmanship, these services deliver solutions that balance lightweight strength, durability, and aesthetic appeal. Below, we explore the key features and wide-ranging applications of aluminium deep processing, highlighting why it is a cornerstone of modern manufacturing.

Core Features: Advanced Engineering for Superior Results

Utilizing CNC machining, extrusion, stamping, and forging, aluminium deep processing achieves micron-level accuracy. This ensures components meet strict tolerances, ideal for complex geometries and high-performance requirements.

Customization at Scale

From prototype development to mass production, services are fully adaptable. Clients can specify dimensions, alloys (e.g., 6061, 7075, or custom blends), surface finishes (anodizing, powder coating, polishing), and mechanical properties.

Lightweight & High-Strength Solutions

Aluminium’s inherent strength-to-weight ratio is enhanced through processes like heat treatment and alloying. This makes it ideal for applications where reducing weight without compromising durability is critical.

Surface Excellence

Advanced treatments improve corrosion resistance, wear resistance, and aesthetics. Options include anodizing for color durability, Teflon coatings for non-stick properties, and precision polishing for a mirror finish.

Sustainability Focus

Aluminium is 100% recyclable. Deep processing minimizes waste through efficient material usage and energy-saving techniques, aligning with global sustainability goals.

Applications: Driving Innovation Across Industries

Aluminium’s versatility makes it indispensable in sectors demanding reliability, efficiency, and innovation:

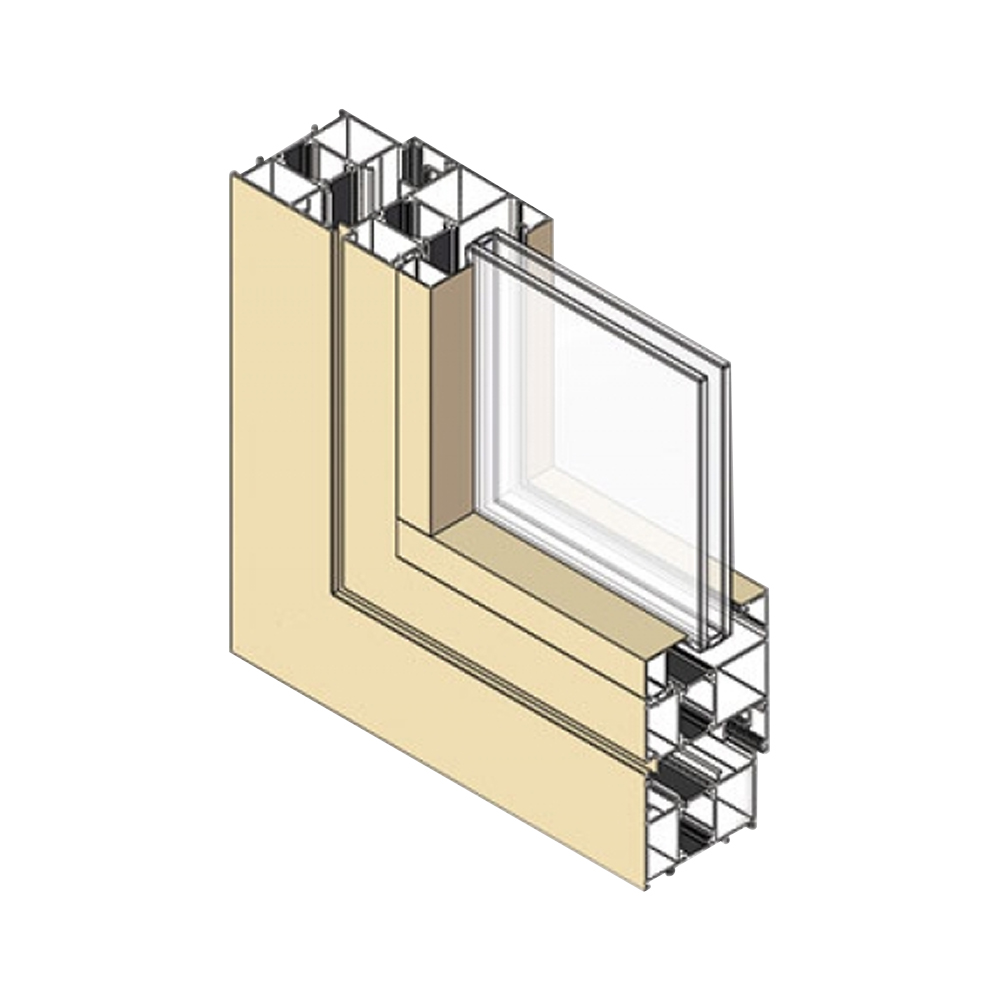

Construction & Architecture

Structural components (frames, beams, facades) for skyscrapers and bridges.

Decorative elements (ceilings, window frames) with anodized finishes for weather resistance.

Automotive & Transportation

Lightweight vehicle parts (engine blocks, chassis, battery trays) to improve fuel efficiency and EV range.

High-strength rail and aerospace components meeting rigorous safety standards.

Electronics & Electrical

Heat sinks for thermal management in CPUs and LED lighting.

Enclosures for sensitive equipment, combining EMI shielding and sleek design.

Industrial Machinery

Custom gears, molds, and conveyor systems resistant to harsh operating conditions.

Corrosion-resistant parts for chemical and marine environments.

Consumer Goods

Durable, lightweight products like premium cookware, sporting equipment, and furniture.

Why Choose Aluminium Deep Processing?

Cost Efficiency : Reduced material waste and energy savings lower long-term costs.

Speed to Market : Rapid prototyping and agile production timelines accelerate product launches.

Technical Expertise : Engineers collaborate closely with clients to optimize designs for manufacturability.

Global Compliance : Adherence to ISO, ASTM, and industry-specific standards ensures reliability.

Partner with Excellence

Aluminium deep processing is not just a service—it’s a strategic advantage. Whether you need a single prototype or large-scale production, our end-to-end solutions empower your projects with precision, innovation, and sustainability.

Contact us today to discuss your requirements and discover how aluminium can elevate your next project.

-

-

With the growth of global demand for renewable energy, the application of industrial aluminium profiles in the field of new energy is promising. Especially in the field of solar and wind energy, alumi...

READ MORE -

Industrial aluminium profiles become new favourite as construction industry turns to green materials

The construction industry is progressively adopting environmentally friendly materials to reduce its impact on the environment. Industrial aluminium profiles are one of the preferred materials for gre...

READ MORE -

In recent years, automobile lightweight has attracted more and more attention, which is of extremely important significance to automobiles. Realize the lightweight of the car, the weight of the whole ...

READ MORE -

I believe that anyone who knows industrial aluminum profiles should know the industrial aluminum profile frame. Here I will give you a brief introduction: Industrial aluminum profile is also called fr...

READ MORE

English

English 日本語

日本語 한국어

한국어