In the manufacturing industry, advances in CNC machining technology cannot be made without the support of high-quality materials. Industrial aluminium profiles have become an indispensable material fo...

READ MOREAluminum Extrusion Mold Customization

Custom aluminum extrusion molds provide unmatched precision, allowing manufacturers to achieve complex geometries with tight tolerances. Unlike standard molds, which may have limitations in design and fit, customized molds ensure that every component matches exact specifications. This level of precision is critical for industries where high accuracy is essential, such as aerospace, medical devices, and high-performance machinery. By investing in custom molds, businesses can enhance the reliability and quality of their final products, reducing defects and improving customer satisfaction.

Boosting Efficiency and Reducing Production Costs

One of the primary advantages of aluminum extrusion mold customization is the ability to optimize production efficiency. Custom molds streamline the manufacturing process, reducing the need for additional machining and post-processing work. This not only saves time but also minimizes material waste, leading to significant cost savings. Companies can benefit from faster production cycles, improved material utilization, and lower overall expenses, making custom molds an economical choice for both small-scale and large-scale manufacturing.

Durable and High-Performance Mold Solutions

Custom aluminum extrusion molds are designed with durability in mind, ensuring a long lifespan and consistent performance even under demanding conditions. By using high-quality materials and advanced engineering techniques, these molds can withstand high pressures and extreme temperatures without compromising their structural integrity. This durability is particularly important for industries such as automotive and construction, where components need to maintain their strength and function over time. Investing in robust, custom molds leads to fewer replacements and maintenance costs, further enhancing the value of production.

Versatility Across Multiple Industries

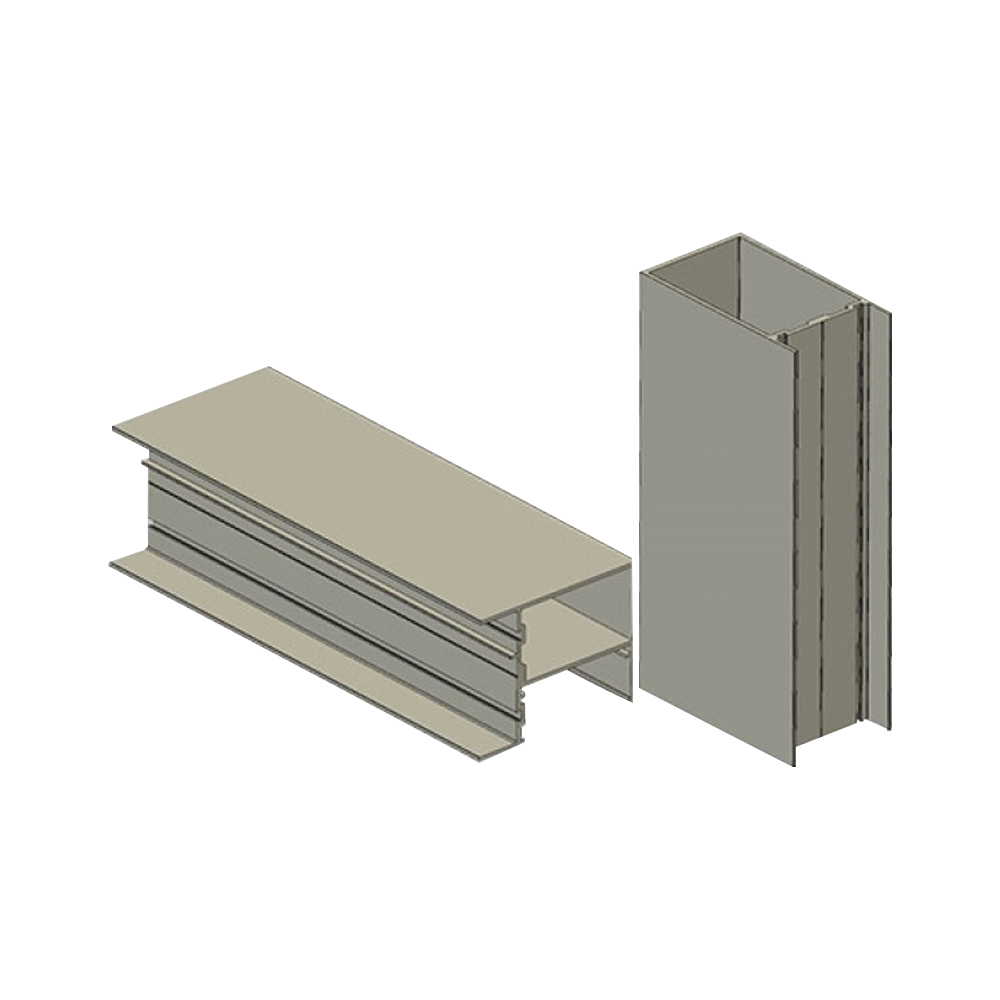

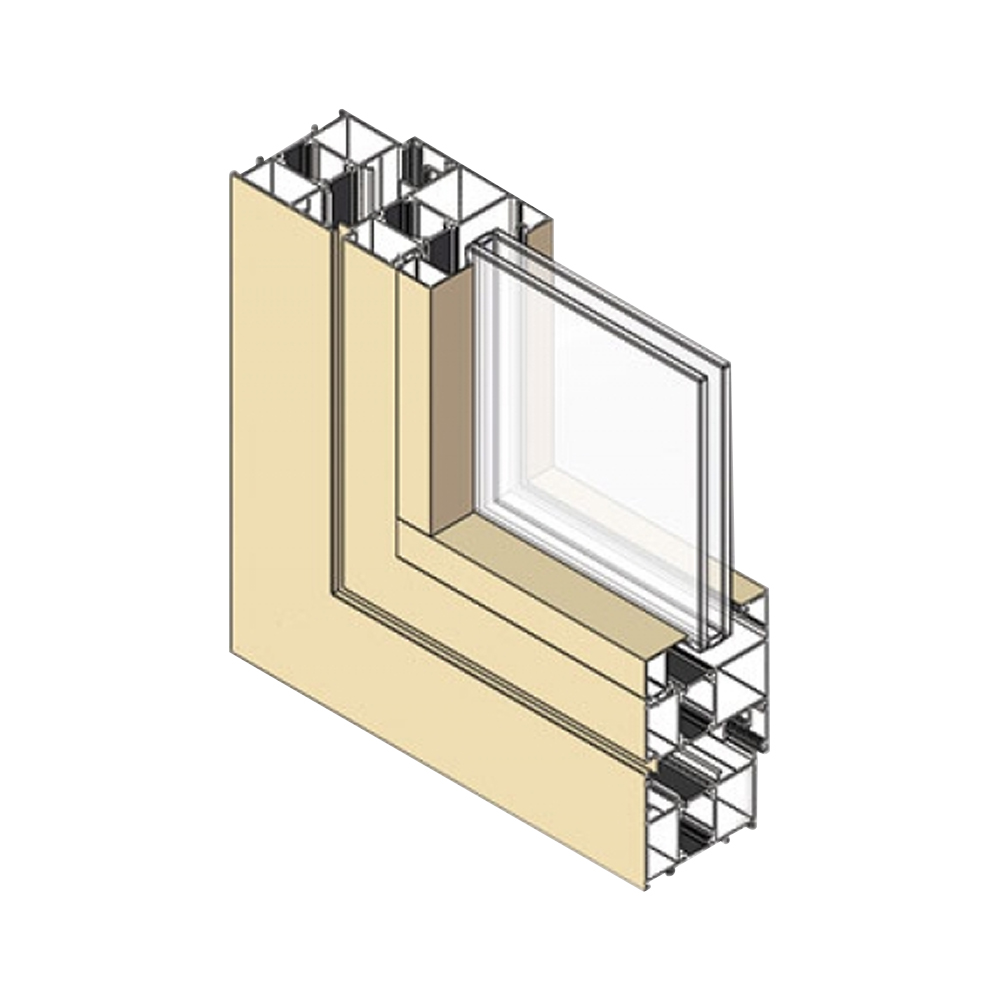

From architectural structures to consumer electronics, custom aluminum extrusion molds cater to a wide range of industries. In the construction sector, they enable the production of sleek and modern window frames, doors, and curtain walls. In the automotive industry, they contribute to the creation of lightweight yet strong vehicle components that enhance fuel efficiency and safety. Electronics manufacturers rely on custom extrusion molds to produce intricate heat sinks and casings that improve device performance. The adaptability of these molds makes them an indispensable tool for businesses looking to innovate and expand their product offerings.

Gaining a Competitive Edge Through Innovation

Customization allows businesses to push the boundaries of design and functionality, giving them a competitive advantage in their respective markets. By utilizing tailored molds, companies can develop unique, proprietary components that set their products apart from the competition. Whether it’s creating aesthetically appealing architectural elements, high-performance industrial parts, or precision-engineered mechanical components, custom molds enable businesses to meet evolving market demands with innovative solutions. This level of design flexibility ensures that companies stay ahead in an increasingly competitive landscape.

Maximizing Product Quality and Consistency

Consistency is key in manufacturing, and custom aluminum extrusion molds ensure that every piece produced meets the same high standards. Whether manufacturing thousands of identical parts for mass production or specialized components for niche applications, these molds guarantee uniformity in shape, size, and surface finish. This not only enhances the overall quality of the final product but also reduces variability and defects, leading to higher customer satisfaction and brand reputation.

Conclusion: The Smart Choice for Modern Manufacturing

Aluminum extrusion mold customization is a game-changer for businesses seeking precision, efficiency, and innovation. With benefits ranging from cost savings and durability to enhanced design flexibility and industry adaptability, custom molds provide an effective solution for optimizing production. By choosing tailored mold solutions, companies can boost productivity, improve product quality, and maintain a competitive edge in the marketplace. Whether for large-scale production or specialized applications, customized aluminum extrusion molds are the key to achieving superior performance and long-term success.

information to be updated

-

-

With the growth of global demand for renewable energy, the application of industrial aluminium profiles in the field of new energy is promising. Especially in the field of solar and wind energy, alumi...

READ MORE -

Industrial aluminium profiles become new favourite as construction industry turns to green materials

The construction industry is progressively adopting environmentally friendly materials to reduce its impact on the environment. Industrial aluminium profiles are one of the preferred materials for gre...

READ MORE -

In recent years, automobile lightweight has attracted more and more attention, which is of extremely important significance to automobiles. Realize the lightweight of the car, the weight of the whole ...

READ MORE -

I believe that anyone who knows industrial aluminum profiles should know the industrial aluminum profile frame. Here I will give you a brief introduction: Industrial aluminum profile is also called fr...

READ MORE

English

English 日本語

日本語 한국어

한국어