In the manufacturing industry, advances in CNC machining technology cannot be made without the support of high-quality materials. Industrial aluminium profiles have become an indispensable material fo...

READ MOREArchitectural Aluminum Extrusion Profiles

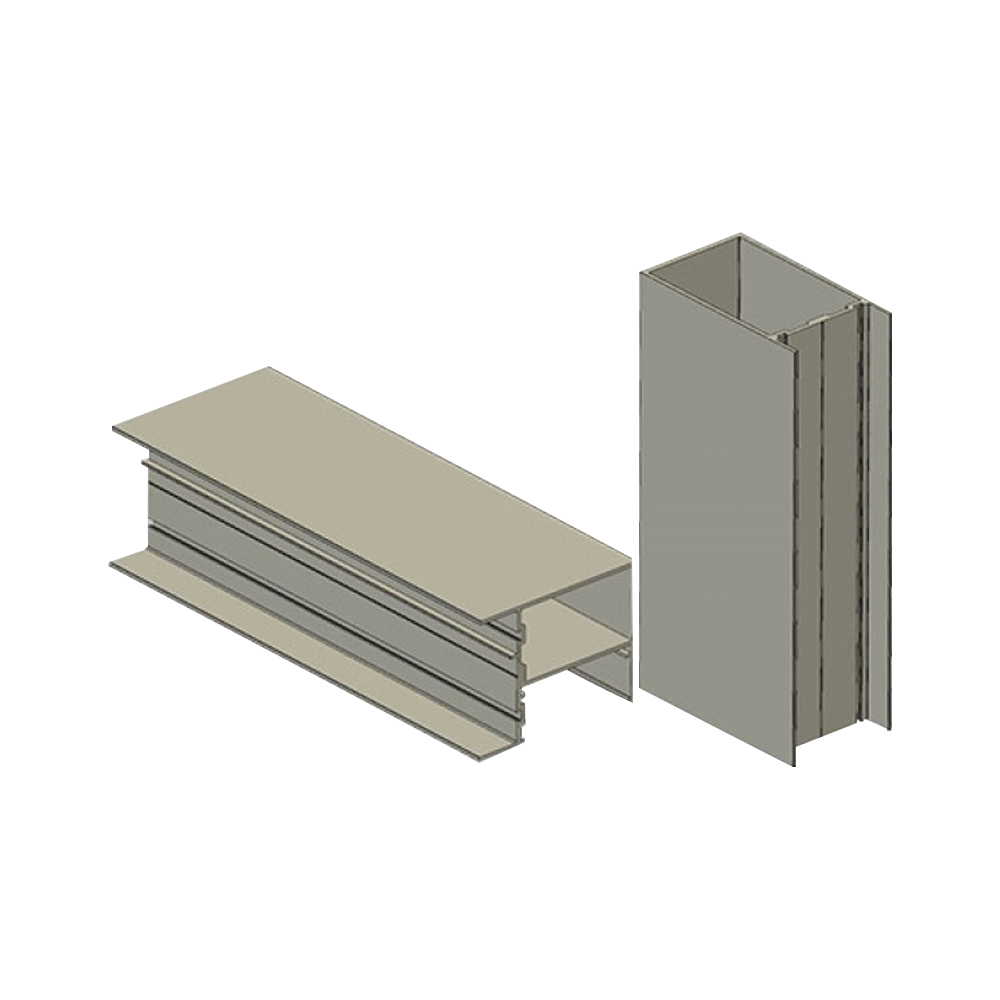

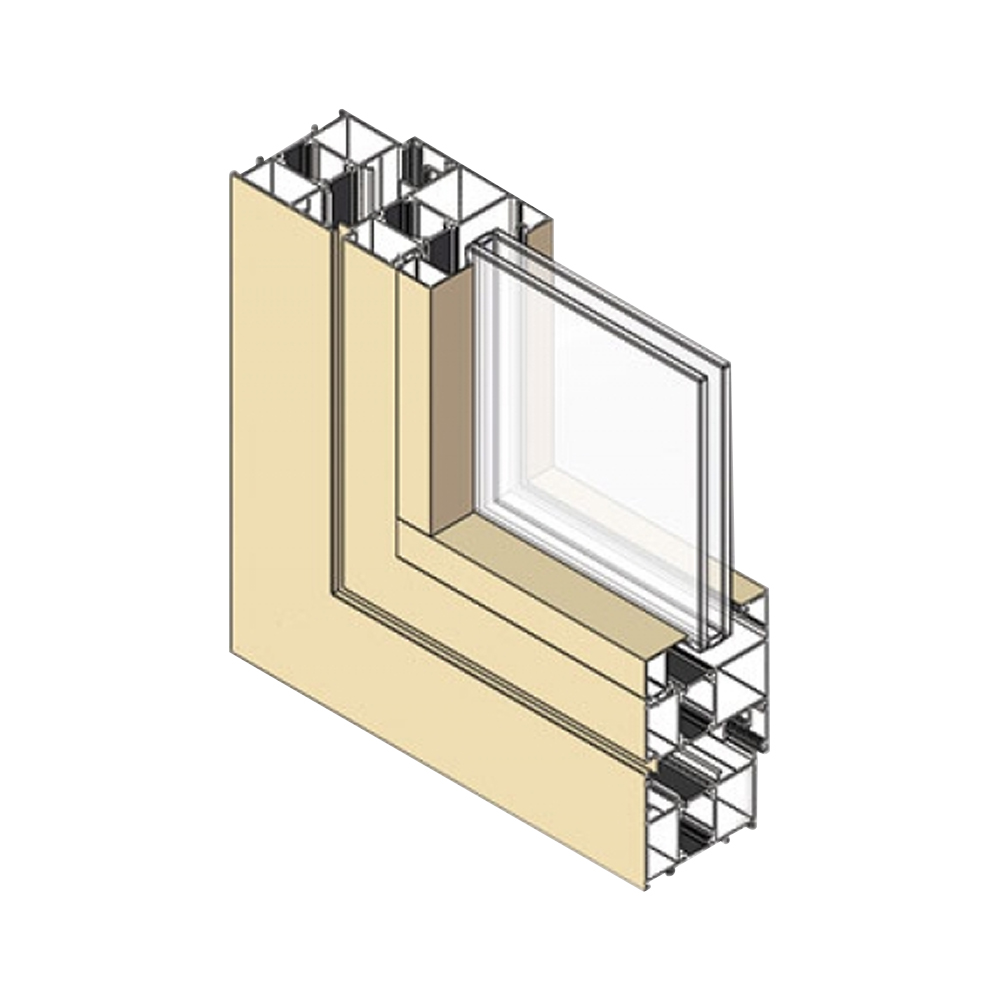

Architectural aluminum extrusion profiles are engineered to meet the rigorous demands of contemporary construction. Despite their lightweight nature, these profiles exhibit exceptional strength-to-weight ratios, enabling them to withstand structural stresses without compromising on agility during installation. Their inherent resistance to corrosion—whether from moisture, UV exposure, or environmental pollutants—ensures longevity even in harsh climates, from coastal areas to industrial zones. This durability translates to reduced maintenance costs and fewer replacements over time, making them a cost-effective solution for both commercial and residential projects. Furthermore, aluminum’s non-combustible properties enhance fire safety, aligning with stringent building codes and sustainability standards.

Design Flexibility and Aesthetic Versatility

One of the most compelling advantages of aluminum extrusion profiles lies in their adaptability to diverse architectural visions. Through advanced extrusion processes, these profiles can be customized into intricate shapes, curves, and modular systems, empowering architects to push creative boundaries. Surface finishes such as anodizing, powder coating, or wood-grain texturing offer endless aesthetic possibilities, blending seamlessly with modern minimalist designs or traditional motifs. This versatility extends to functional applications: slim-profile curtain wall systems maximize natural light while maintaining structural integrity, and customizable door/window frames accommodate energy-efficient glazing. The ability to integrate seamlessly with other materials—such as glass, steel, or composite panels—further elevates their role in hybrid design solutions.

Sustainability and Energy Efficiency

Aluminum extrusion profiles are pivotal in advancing sustainable construction practices. Aluminum is 100% recyclable with no degradation in quality, significantly reducing the carbon footprint of building projects. The production process itself has evolved to emphasize energy efficiency, with many manufacturers using renewable energy sources and closed-loop recycling systems. In terms of performance, thermally broken aluminum profiles minimize heat transfer, enhancing insulation and reducing reliance on HVAC systems. Combined with double or triple glazing, these systems achieve high U-values, contributing to LEED certification and other green building standards. By lowering energy consumption over a building’s lifecycle, aluminum profiles align with global efforts to combat climate change while delivering long-term economic benefits.

Applications Across Diverse Construction Needs

The adaptability of architectural aluminum extrusions makes them indispensable across a spectrum of applications. In commercial buildings, curtain wall systems create expansive glass façades that symbolize modernity while providing weather resistance and acoustic insulation. For residential projects, sleek aluminum window and door frames offer slim sightlines and enhanced security. In infrastructure, scaffold aluminum profiles ensure safe, lightweight temporary structures during construction, while modular furniture systems leverage aluminum’s durability for ergonomic, space-efficient designs. Even in niche areas like solar panel mounting systems or smart building facades with dynamic shading, aluminum’s precision engineering and lightweight properties enable innovative solutions.

Precision Engineering for Future-Ready Infrastructure

Advancements in extrusion technology have elevated aluminum profiles to a cornerstone of smart, high-performance buildings. Computer-aided design (CAD) and precision tooling allow for micron-level tolerances, ensuring seamless assembly and compatibility with automated construction techniques. Prefabricated aluminum components reduce on-site labor and waste, accelerating project timelines. Additionally, aluminum’s compatibility with IoT-enabled systems—such as embedded sensors for monitoring structural health or adaptive shading systems—positions it as a key material for smart cities and resilient infrastructure. As architects increasingly prioritize modularity and scalability, aluminum extrusions provide a scalable platform for future upgrades, ensuring buildings remain adaptable to evolving technological and environmental challenges.

In conclusion, architectural aluminum extrusion profiles represent the synergy of innovation, sustainability, and practicality. Their unique combination of strength, design freedom, and eco-friendliness positions them as the backbone of modern construction, enabling structures that are as efficient as they are inspiring. As the industry continues to evolve, aluminum profiles will undoubtedly remain at the forefront of architectural excellence.

-

-

With the growth of global demand for renewable energy, the application of industrial aluminium profiles in the field of new energy is promising. Especially in the field of solar and wind energy, alumi...

READ MORE -

Industrial aluminium profiles become new favourite as construction industry turns to green materials

The construction industry is progressively adopting environmentally friendly materials to reduce its impact on the environment. Industrial aluminium profiles are one of the preferred materials for gre...

READ MORE -

In recent years, automobile lightweight has attracted more and more attention, which is of extremely important significance to automobiles. Realize the lightweight of the car, the weight of the whole ...

READ MORE -

I believe that anyone who knows industrial aluminum profiles should know the industrial aluminum profile frame. Here I will give you a brief introduction: Industrial aluminum profile is also called fr...

READ MORE

English

English 日本語

日本語 한국어

한국어