In the manufacturing industry, advances in CNC machining technology cannot be made without the support of high-quality materials. Industrial aluminium profiles have become an indispensable material fo...

READ MOREAluminum Extrusion Profiles

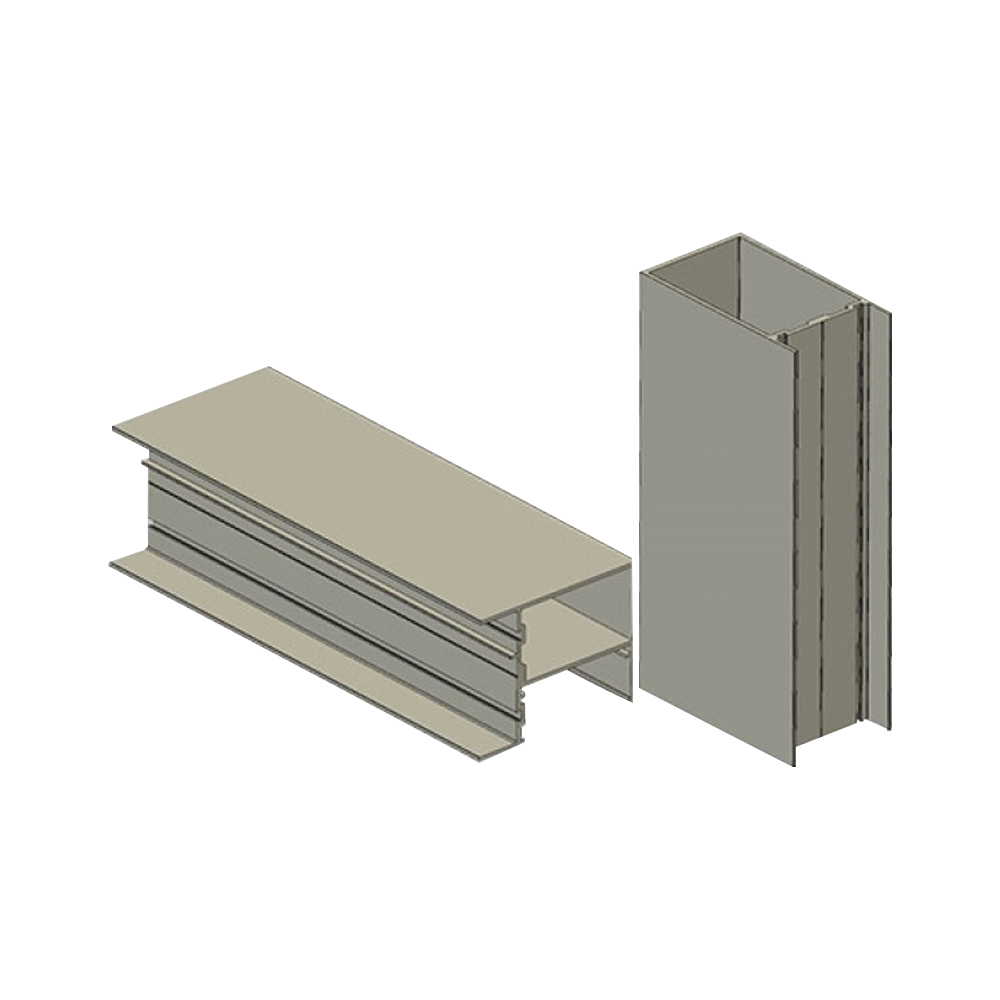

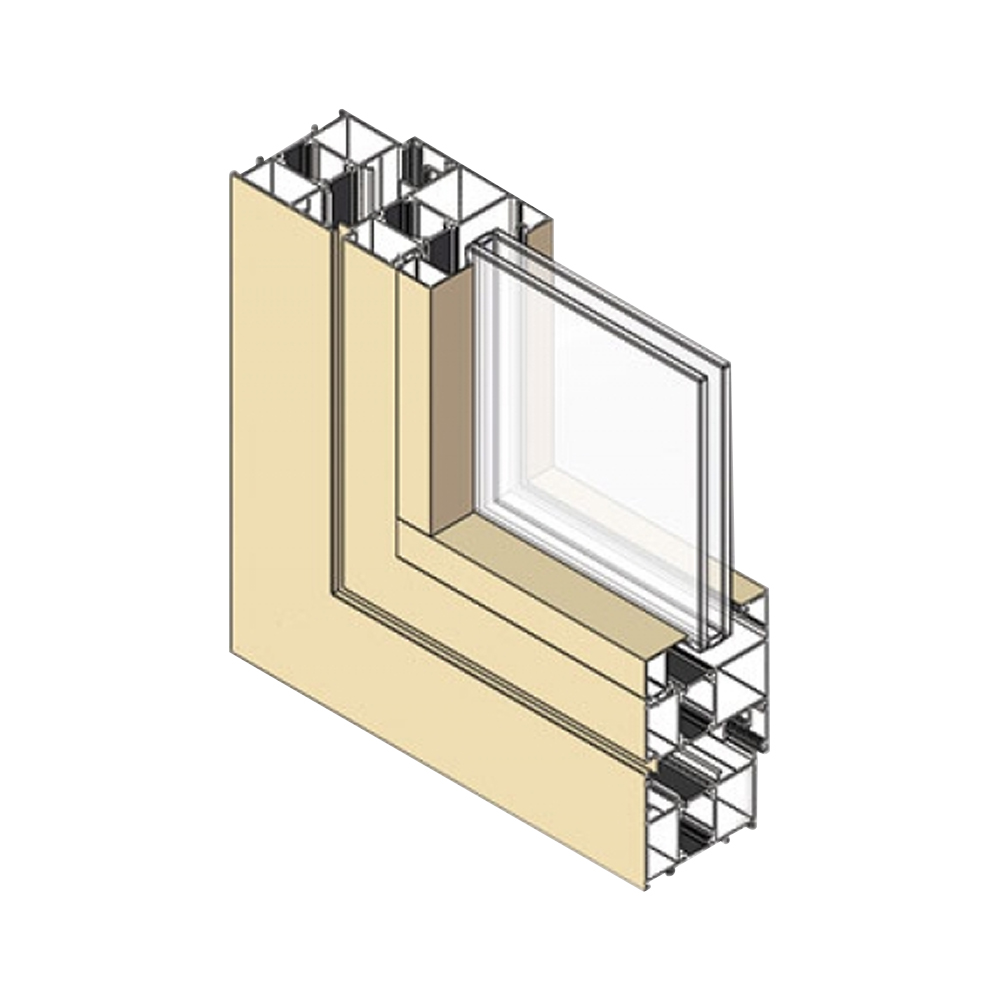

In the realm of contemporary construction and industrial design, aluminum extrusion profiles stand out as a transformative solution, seamlessly merging aesthetic sophistication with exceptional functional performance. These profiles are not merely materials but engineered systems designed to address the evolving demands of diverse industries. From architectural marvels to automotive innovations, aluminum extrusions offer unparalleled adaptability, enabling designers and engineers to push the boundaries of creativity while maintaining structural integrity.

Precision Engineering for Superior Performance

At the core of aluminum extrusion technology lies advanced manufacturing processes that ensure precision and consistency. The extrusion process involves forcing aluminum billets through custom-designed dies, creating complex cross-sectional profiles with tight tolerances. This method allows for intricate geometries—such as hollow chambers, interlocking joints, or tapered edges—that optimize strength-to-weight ratios. Modern facilities leverage computer-aided design (CAD) and simulation tools to refine die designs, minimizing material waste and maximizing efficiency. Additionally, alloys like 6063-T5 or 6061-T6 are selected for their balanced mechanical properties, including corrosion resistance, thermal conductivity, and machinability. The result is a product that meets rigorous industry standards while enabling lightweight, energy-efficient solutions.

Surface Treatments: Enhancing Durability and Aesthetics

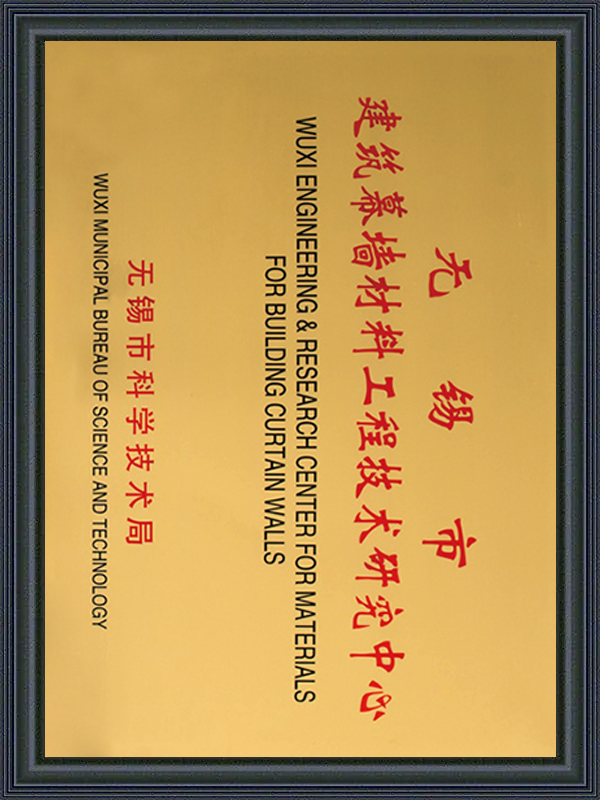

Aluminum’s natural oxide layer provides inherent corrosion resistance, but advanced surface treatments amplify its longevity and visual appeal. Anodizing, a electrochemical process, thickens the oxide layer, enhancing hardness and enabling color customization through dye absorption. This treatment is ideal for architectural applications like curtain walls or window frames, where UV stability and abrasion resistance are critical. Powder coating offers another versatile option, applying thermoset polymer layers that resist chipping, fading, and chemical exposure. For industrial components requiring a sleek, non-reflective finish, brushing or bead blasting creates a matte texture while preserving the material’s metallic luster. These treatments are tailored to environmental conditions—marine-grade anodizing for coastal installations or antimicrobial coatings for healthcare environments—ensuring compliance with project-specific requirements.

Applications Across Industries: Versatility in Action

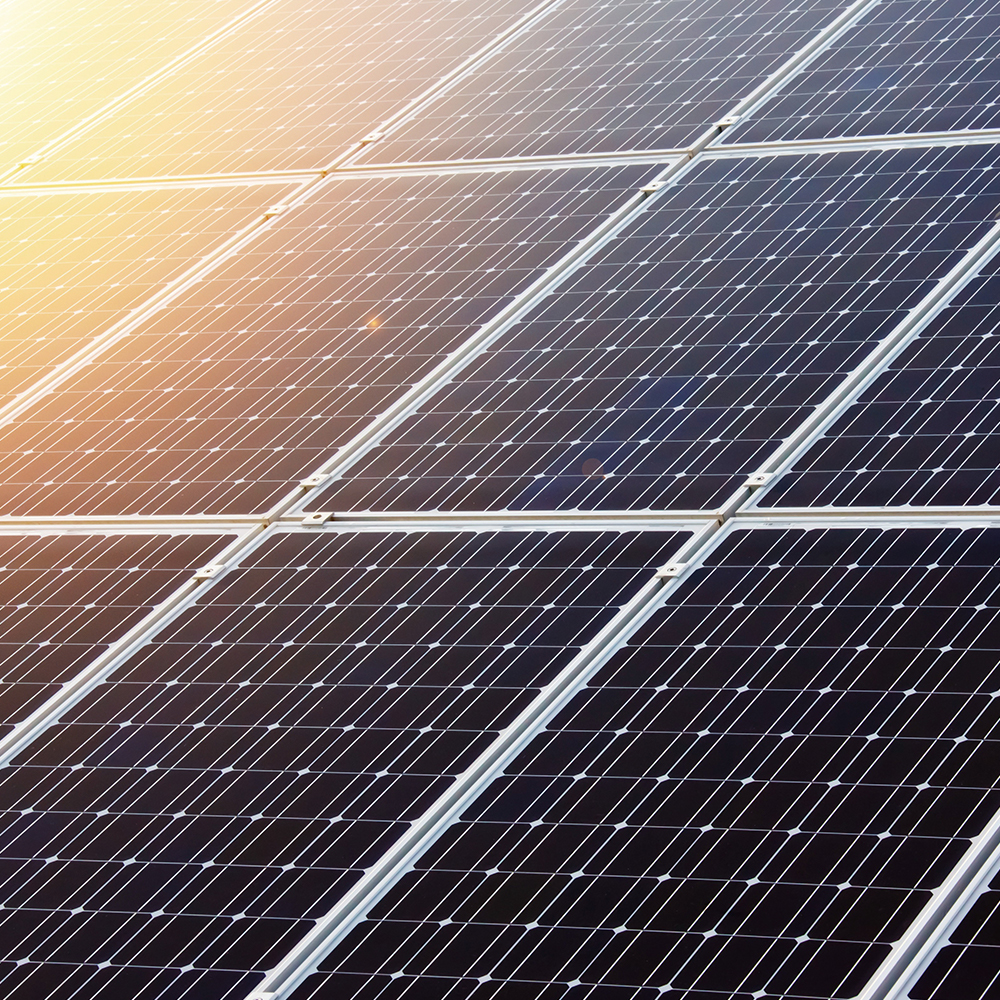

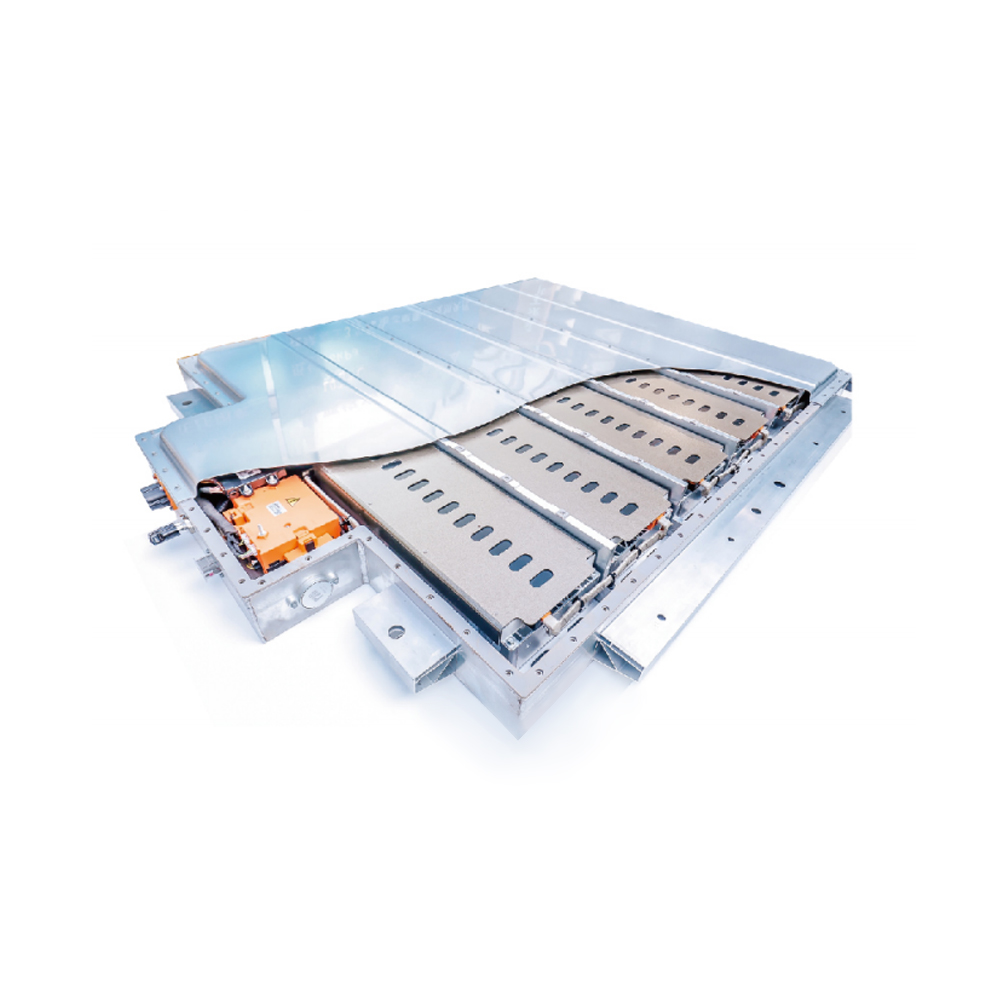

The adaptability of aluminum extrusions drives their adoption across sectors. In architecture, they form the backbone of sustainable building systems, from energy-efficient thermal breaks in façades to modular framing for solar panels. Automotive engineers utilize extruded profiles to reduce vehicle weight without compromising safety, integrating them into chassis, battery enclosures, and roof rails. In consumer goods, sleek extruded components elevate furniture design, lighting fixtures, and electronics enclosures. Even niche applications, such as robotic arms in automation or heat sinks in electronics, benefit from aluminum’s thermal management capabilities. This versatility stems from the material’s ability to be customized in shape, size, and finish, aligning with the unique demands of each project.

Sustainability and Future-Forward Innovation

Aluminum’s infinite recyclability positions extrusion profiles as a cornerstone of sustainable design. Over 75% of all aluminum ever produced remains in use today, significantly reducing the carbon footprint of new projects. Manufacturers further minimize environmental impact by adopting closed-loop water systems, renewable energy in production, and low-VOC coatings. Emerging trends, such as 3D-printed dies for rapid prototyping or AI-driven quality control, promise even greater efficiency. As industries prioritize circular economies, aluminum extrusions will continue to lead as a material that harmonizes ecological responsibility with cutting-edge performance.

Conclusion: A Smart Investment for Visionary Projects

Aluminum extrusion profiles embody the synergy of art and engineering, offering solutions that transcend conventional limitations. Their blend of precision, customization, and sustainability makes them indispensable for forward-thinking professionals. By choosing these profiles, designers and builders invest in a material that not only elevates today’s projects but also pioneers the innovations of tomorrow. Explore the possibilities—where every profile is a testament to excellence, crafted to exceed expectations in form, function, and environmental stewardship.

-

-

With the growth of global demand for renewable energy, the application of industrial aluminium profiles in the field of new energy is promising. Especially in the field of solar and wind energy, alumi...

READ MORE -

Industrial aluminium profiles become new favourite as construction industry turns to green materials

The construction industry is progressively adopting environmentally friendly materials to reduce its impact on the environment. Industrial aluminium profiles are one of the preferred materials for gre...

READ MORE -

In recent years, automobile lightweight has attracted more and more attention, which is of extremely important significance to automobiles. Realize the lightweight of the car, the weight of the whole ...

READ MORE -

I believe that anyone who knows industrial aluminum profiles should know the industrial aluminum profile frame. Here I will give you a brief introduction: Industrial aluminum profile is also called fr...

READ MORE

English

English 日本語

日本語 한국어

한국어