-

Aluminum Profiles Surface Treatment Aluminum Profiles Surface Treatment

Aluminum Profiles Surface Treatment Aluminum Profiles Surface Treatment -

Automotive Parts CNC Machining Industrial Automotive Parts Precision Machining

Automotive Parts CNC Machining Industrial Automotive Parts Precision Machining -

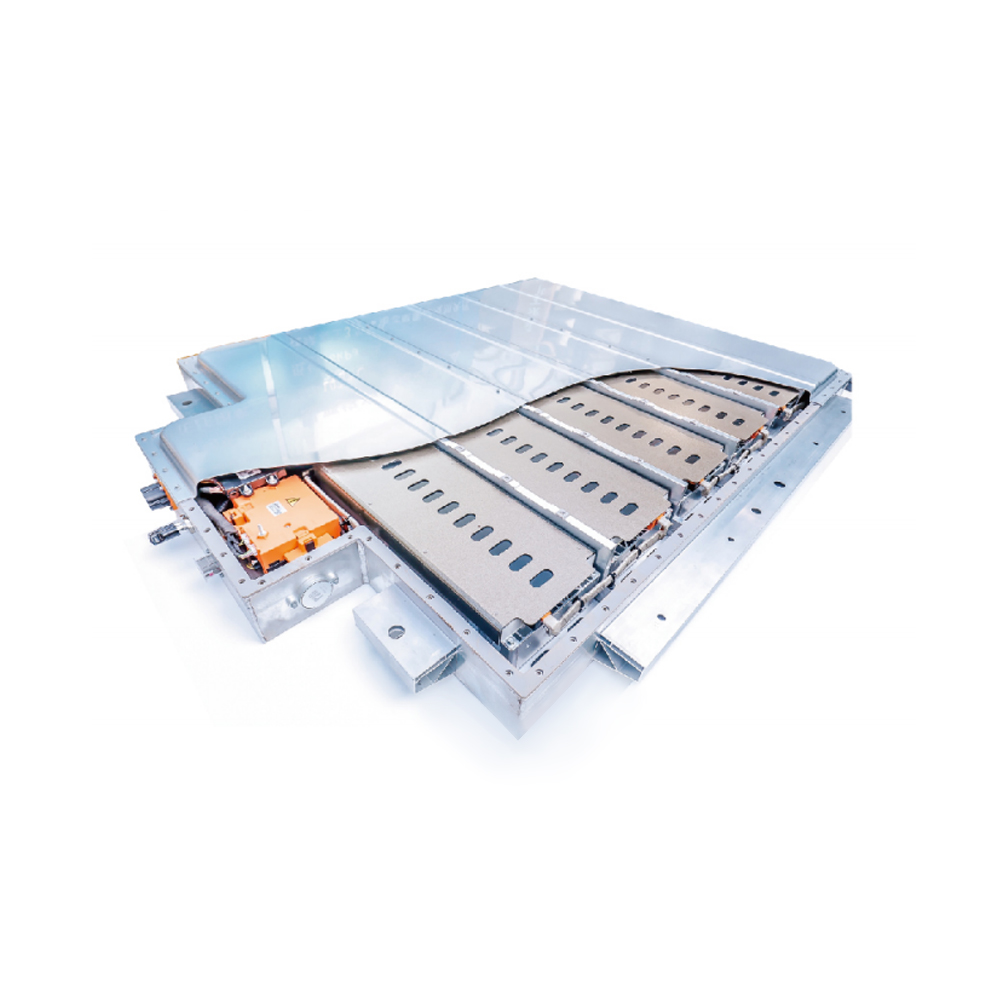

Aluminium Extrusion for Energy Storage Battery Pack New Energy Aluminum Extrusions Profiles

Aluminium Extrusion for Energy Storage Battery Pack New Energy Aluminum Extrusions Profiles -

Photovoltaic Mounting Bracket Aluminium Profiles New Energy Aluminum Extrusions Profiles

Photovoltaic Mounting Bracket Aluminium Profiles New Energy Aluminum Extrusions Profiles -

Car Roof Rack Aluminum Extrusion Profiles Automotive Aluminum Extrusion Profiles

Car Roof Rack Aluminum Extrusion Profiles Automotive Aluminum Extrusion Profiles -

Car Aluminum Pedals Profile Automotive Aluminum Extrusion Profiles

Car Aluminum Pedals Profile Automotive Aluminum Extrusion Profiles -

Aluminum Heat Sink Profiles Industrial Aluminum Extrusion Profiles

Aluminum Heat Sink Profiles Industrial Aluminum Extrusion Profiles -

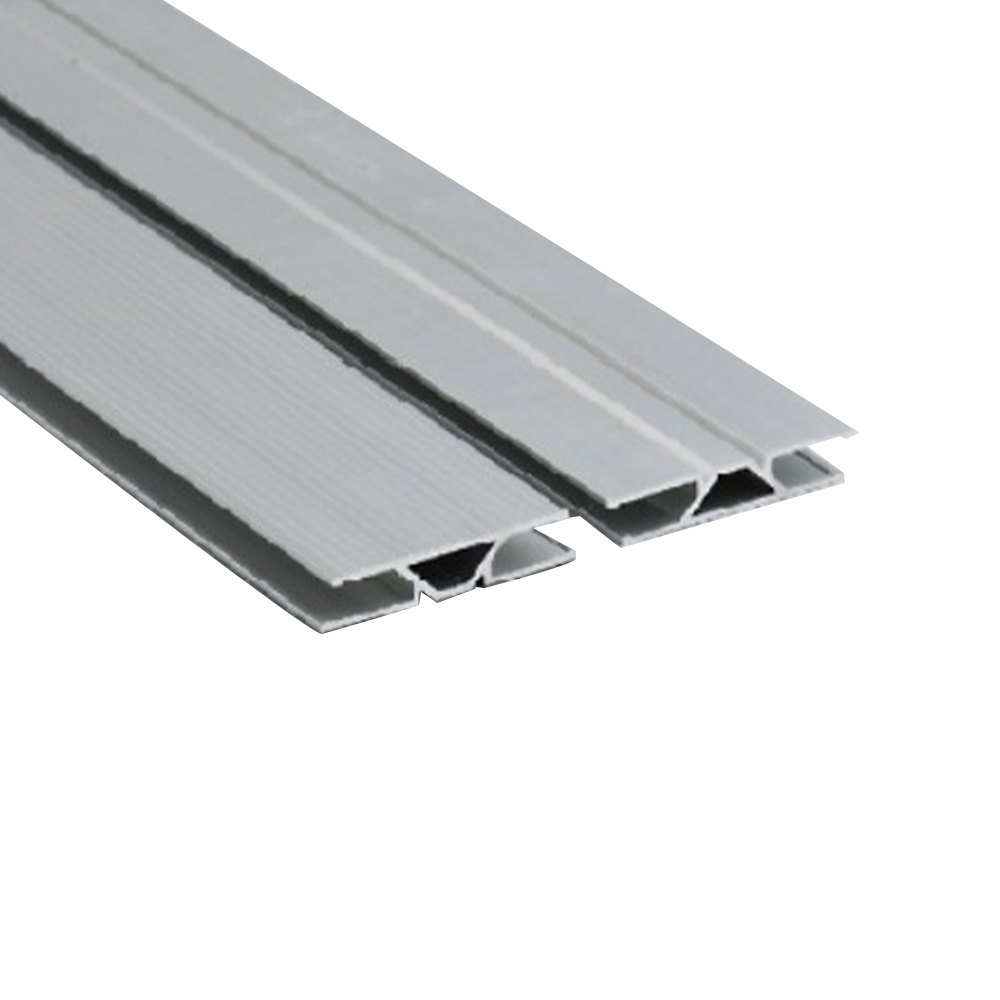

Industrial Assembly Line Aluminum Profiles Industrial Aluminum Extrusion Profiles

Industrial Assembly Line Aluminum Profiles Industrial Aluminum Extrusion Profiles -

Aluminium Rail Transit Profiles Industrial Aluminum Extrusion Profiles

Aluminium Rail Transit Profiles Industrial Aluminum Extrusion Profiles -

Aluminum Fence Profiles Architectural Aluminum Extrusion Profiles

Aluminum Fence Profiles Architectural Aluminum Extrusion Profiles -

Scaffold Aluminum Profiles Architectural Aluminum Extrusion Profiles

Scaffold Aluminum Profiles Architectural Aluminum Extrusion Profiles -

Furniture Aluminium Profiles Architectural Aluminum Extrusion Profiles

Furniture Aluminium Profiles Architectural Aluminum Extrusion Profiles

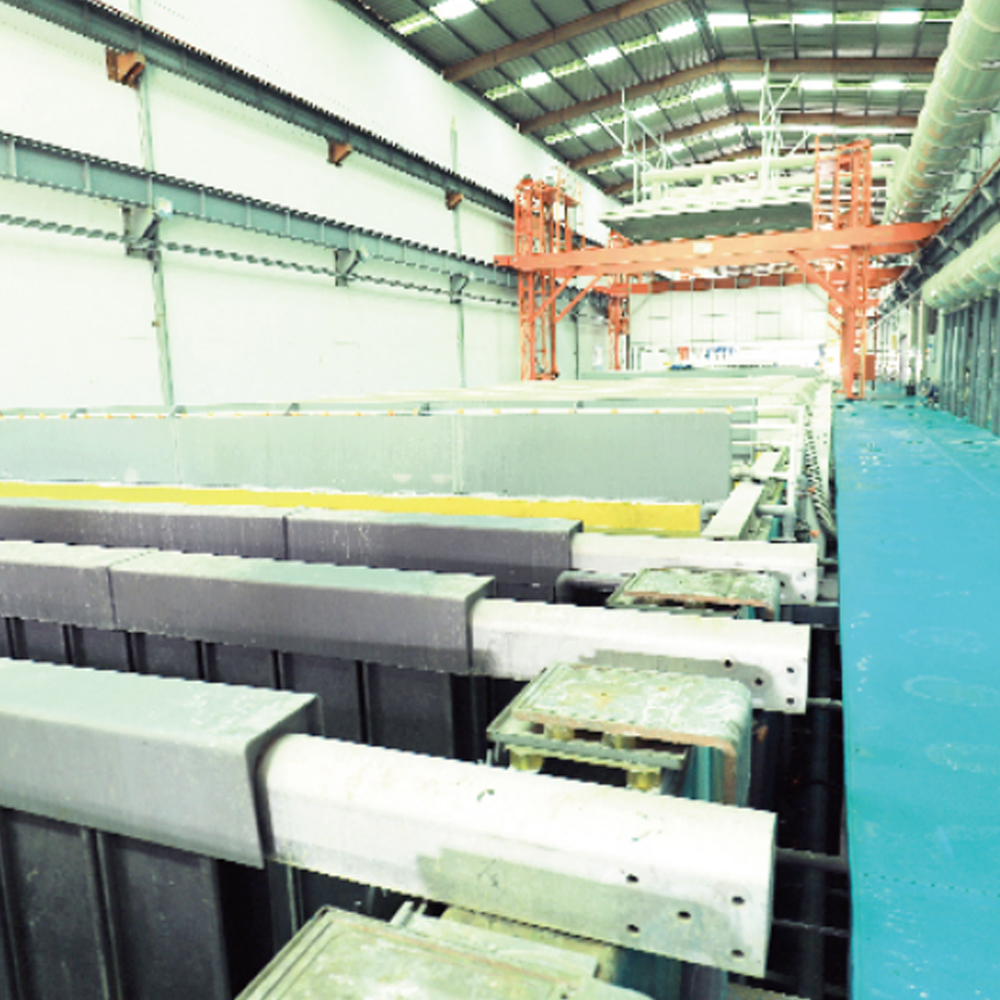

Industrial Assembly Line Aluminum Profiles

Industrial Assembly Line Aluminum Profiles are the backbone of modern manufacturing, providing a lightweight, durable, and highly flexible solution for efficient production systems. These profiles offer excellent strength-to-weight ratios, corrosion resistance, and easy machinability, making them ideal for constructing sturdy and adaptable assembly line structures.With their modular design, Industrial Assembly Line Aluminum Profiles allow for quick assembly, expansion, and reconfiguration, reducing downtime and improving productivity. They are widely used in workstations, conveyor systems, safety enclosures, and robotic automation, ensuring seamless integration with industrial processes. Their precision and stability enhance workflow efficiency, while their smooth surfaces ensure easy cleaning and maintenance.Whether for large-scale manufacturing or small production setups, Industrial Assembly Line Aluminum Profiles provide the perfect combination of strength, adaptability, and sustainability.

1. Modular Flexibility for Adaptive Workflows

Quick Assembly : Pre-engineered components enable rapid installation, minimizing downtime during setup or reconfiguration.

Scalable Systems : Expand or modify layouts effortlessly to meet evolving production demands.

Customizable Configurations : Tailor structures to fit unique workspace needs, from conveyor systems to robotic enclosures.

This adaptability ensures manufacturers stay agile in dynamic markets, optimizing floor space and operational efficiency.

2. Versatile Applications Across Industries

Workstations & Ergonomic Solutions : Lightweight frames support ergonomic designs, enhancing worker comfort and productivity.

Conveyor Systems : Smooth surfaces and precise tolerances ensure seamless material flow in assembly lines.

Safety Enclosures & Guards : Protect machinery and personnel with durable, non-conductive barriers.

Robotics Integration : Stable platforms support automation equipment, reducing vibration and errors.

From automotive to electronics manufacturing, these profiles serve as the backbone for diverse industrial applications.

3. Sustainability & Cost Efficiency

Eco-Friendly Material : 100% recyclable, reducing environmental impact and aligning with green manufacturing goals.

Long Lifespan : Resists wear and tear, lowering replacement costs over time.

Energy Savings : Lightweight structures reduce energy consumption in machinery and transportation.

4. Precision Engineering & Global Standards

Tight Tolerances : Ensures compatibility with advanced machinery and automation tools.

Smooth Surface Finish : Simplifies cleaning and maintenance, critical for hygiene-sensitive industries.

Compliance with ISO Standards : Meets international quality and safety benchmarks, building client trust.

High-precision profiles guarantee reliability, reducing errors and rework in complex production systems.

Conclusion

Industrial Assembly Line Aluminum Profiles revolutionize manufacturing by blending strength, flexibility, and sustainability. For manufacturers, they offer a future-proof investment—enhancing efficiency, reducing costs, and supporting innovation. Whether scaling production or upgrading facilities, these profiles empower industries to build smarter, safer, and more adaptive systems. Choose aluminum profiles to drive your manufacturing excellence today!

-

In the manufacturing industry, advances in CNC machining technology cannot be made without the support of high-quality materials. Industrial aluminium profiles have become an indispensable material fo...

READ MORE -

With the growth of global demand for renewable energy, the application of industrial aluminium profiles in the field of new energy is promising. Especially in the field of solar and wind energy, alumi...

READ MORE -

Industrial aluminium profiles become new favourite as construction industry turns to green materials

The construction industry is progressively adopting environmentally friendly materials to reduce its impact on the environment. Industrial aluminium profiles are one of the preferred materials for gre...

READ MORE -

In recent years, automobile lightweight has attracted more and more attention, which is of extremely important significance to automobiles. Realize the lightweight of the car, the weight of the whole ...

READ MORE -

I believe that anyone who knows industrial aluminum profiles should know the industrial aluminum profile frame. Here I will give you a brief introduction: Industrial aluminum profile is also called fr...

READ MORE

English

English 日本語

日本語 한국어

한국어